Transportation authorities worldwide value the safety and efficiency of railway operations. Preventing accidents caused by in-service failures of freight rail vehicle wheels is a critical area that demands attention. These failures pose significant public and railroad safety risks and contribute to costly derailments and operational disruptions.

Over the years, various types of railway wheel failures have been identified, each with unique characteristics and underlying causes. This article aims to provide an in-depth exploration of these failures, shedding light on the mechanisms that lead to them and the potential consequences they can have.

Three problematic and widespread wheel failures are vertical split rims (VSRs), shattered rims, and thermal cracks extending into the wheel plate. VSRs happen when the tread cracking near the surface reaches a critical location within the rim, leading to a swift vertical fracture and subsequent material loss. On the other hand, shattered rim failures are caused by subsurface fatigue cracking initiated at voids or inclusions that occur due to Hertzian contact stress.

Our “wheel profile measuring device” provides detailed wheel geometry insights to support safer operations and predictive maintenance planning.

Thermal cracks are a severe type of failure that occurs when transverse fatigue cracks start at the surface of the tread or flange due to significant braking. These cracks can continue to grow during repeated heating cycles and, if they reach a specific size, can propagate into the plate, potentially causing the wheel to become loose on the axle.

This article will explore various types of wheel failures, including less common causes such as manufacturer defects or cracks in the wheel plates that do not extend through the rim. Understanding these failure types is important as they can have serious consequences.

The Importance of Understanding Wheel Failure Mechanisms

It is crucial to develop a deep understanding of the mechanisms that lead to wheel failure to improve the safety and efficiency of railway operations. The causes of derailments are closely examined by authorities, with in-service wheel failures posing a significant risk. It is essential to conduct comprehensive research to unravel the complexities of these mechanisms, develop effective detection techniques and preventive measures, and minimize derailments caused by wheel failure.

Some aspects that need to be studied include the origin of residual stresses, the processes that lead to crack initiation, and the factors that influence crack propagation. By gaining profound insights into these failure modes, the industry can implement targeted strategies to improve wheel design, manufacturing processes, and maintenance practices. A comprehensive understanding of these mechanisms is paramount for mitigating risks, enhancing operational reliability, and ensuring safe and efficient transportation of goods and passengers on railways.

See also: “Train Wheel Inspection“

Common Types of Railway Wheel Failures

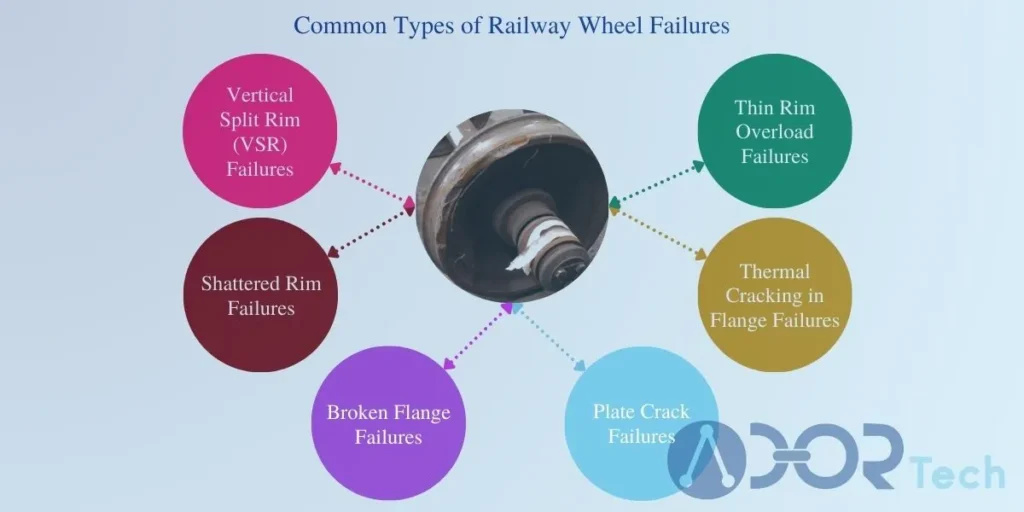

Railway wheel failures are a critical concern for the rail industry, as they pose significant risks to operational safety and efficiency. While various wheel failures exist, this article will focus on the most prevalent and consequential modes that can lead to catastrophic derailments. The common types of railway wheel failures to be discussed in detail are:

- Vertical Split Rim (VSR) Failures

- Shattered Rim Failures

- Broken Flange Failures

- Plate Crack Failures

- Thermal Cracking in Flange Failures

- Thin Rim Overload Failures

The following failure modes represent the main categories of wheel defects that can lead to significant material loss or structural compromise, increasing the risk of derailments. Among these, VSR (Vertical Split Rim) and shattered rim failures are particularly concerning due to their increasing prevalence and the elevated risk of derailment they pose.

Our “In-Track Wheel Measuring System” delivers continuous rail wheel condition monitoring—perfect for detecting cracks, flat spots, and diameter mismatches in motion.

VSRs occur when near-surface tread cracking reaches a critical location within the rim, causing a rapid vertical fracture and subsequent material loss. On the other hand, shattered rim failures are characterized by substantial subsurface fatigue cracks created by Hertzian contact stress, resulting in a distinctive “bullseye” fracture pattern.

While these two failure modes have been the most problematic in recent years, the other types listed above significantly contribute to wheel failures. They will be explored in detail in the subsequent sections. Each failure mode has unique characteristics, underlying causes, and associated risks, requiring a comprehensive understanding of effective prevention and mitigation strategies.

See also: “Mobile Measuring System for Wheel Profile“

Vertical Split Rim (VSR) Failures

A Vertical Split Rim (VSR) failure is identified by a vertical crack that starts from a horizontal crack near the tread surface. When the horizontal crack reaches an area of tensile axial residual stress within the rim, it turns downward and rapidly spreads in the vertical direction. This vertical crack keeps growing, often with intermittent pauses, until a substantial part of the rim face breaks off entirely.

Causes and Occurrence:

The primary cause of VSR failures is the development of tensile axial residual stress in the wheel rim during service. This stress is believed to be induced by deformation of the tread surface due to rolling contact loads. The tensile stress subsurface balances the compressive stress on the tread surface. The horizontal crack that leads to VSR failure can originate from various mechanisms, including shelling, spalling, rolling contact fatigue (RCF), thermal cracking, or a phenomenon known as “delamination.” Delamination is characterized by subsurface fatigue cracking caused by shear stresses, typically 0.5 to 1.0 inch below the tread surface.

Characteristics:

VSR failures exhibit several distinct characteristics:

- Occurrence: VSR failures are primarily observed in North American heavy haul freight operations, particularly in the western United States and Canada. They are rare in passenger rail and international freight operations.

- Wheel Type: VSR failures predominantly occur in heat-treated Class C wheels with rim quenching, which is widely used in the North American freight industry.

- Impacting Conditions: Many VSR failures are associated with high-impact conditions, often measured by Wheel Impact Load Detectors (WILD) and hollow tread wear.

- Rim Thickness: VSR wheels tend to have thinner rims than the general wheel population, although a direct correlation between rim thickness and VSR failures is inconclusive.

- Seasonal Variation: VSR failures are more prevalent during winter, potentially due to various environmental and operational factors.

- Fracture Pattern: A brittle overload fracture with oxidation characterizes the vertical fracture in a VSR failure. The fracture typically removes a portion of the front or back rim face, occasionally including the flange.

Understanding and mitigating VSR failures is crucial for enhancing rail safety and reducing the risk of derailments caused by catastrophic wheel failures. Ongoing research and industry collaboration are essential to unraveling the complex mechanisms behind VSR failures and developing effective prevention and detection strategies.

Shattered Rim Failures

Shattered rim failures present a significant challenge in the rail industry, carrying considerable risks for safe and effective operations. In contrast to Vertical Split Rim (VSR) failures, which involve a vertical crack running through the rim, shattered rim failures are identified by a large subsurface fatigue crack resulting from Hertzian contact stress.

A shattered rim failure occurs when a considerable section of the wheel’s rim breaks off due to a subsurface fatigue crack. This fatigue crack, often known as a “bullseye” fracture, is approximately parallel to the tread surface and is caused by Hertzian contact stress.

Causes and Occurrence:

Manufacturing defects, such as porosity or inclusions within the wheel material, primarily cause shattered rim failures. When combined with the cyclical Hertzian contact stress during operation, these defects can initiate and propagate subsurface fatigue cracks.

Factors contributing to shattered rim failures include:

- Wheel Manufacturing: Improvements in manufacturing processes, including better control over porosity and inclusions, have helped reduce shattered rim failures.

- Wheel Wear: As wheels wear and undergo truing operations, the distance between the tread surface and subsurface defects decreases, bringing the defects closer to the Hertzian contact stress zone.

- Wheel Impact Conditions: As measured by Wheel Impact Load Detectors (WILD), high-impact conditions have been associated with an increased risk of shattered rim failures.

Characteristics:

Shattered rim failures exhibit distinct characteristics:

- Fracture Pattern: The characteristic “bullseye” fracture pattern results from the subsurface fatigue crack propagation parallel to the tread surface.

- Rim Thickness: While not a direct cause, shattered rim failures tend to occur more frequently in wheels with thinner rims, as the defects are closer to the contact stress zone.

- Service Life: Similar to VSR failures, shattered rim failures typically occur on wheels with an average service life of approximately ten years.

- Seasonal Variation: Like VSR failures, shattered rim failures are more prevalent during winter, potentially due to environmental and operational factors.

Mitigating shattered rim failures requires a comprehensive approach, including stringent manufacturing quality controls, proactive removal of high-risk wheels, and monitoring of wheel impact conditions. Additionally, ongoing research efforts aim to understand the mechanisms behind these failures further and develop effective prevention and detection strategies.

By addressing VSR and shattered rim failures, the rail industry can enhance safety, reduce the risk of derailments, and improve railway operations’ overall reliability and efficiency.

Broken Flange Failures

In additionally to Vertical Split Rim (VSR) and Shattered Rim failures, Broken Flange failures present another considerable risk to the safety and effectiveness of rail operations. These failures entail breaking and separating parts of the wheel’s flange, compromising the wheel’s ability to steer the rail vehicle along the track.

A broken flange failure occurs when a part of the wheel’s flange fractures due to excessive thinning or cracking. The flange is a critical part of the wheel, tasked with maintaining the wheel centered on the rail and preventing derailment.

Causes and Occurrence:

Broken Flange failures can occur due to various reasons, including:

- Excessive Wear: Prolonged service and wear can lead to a gradual thinning of the flange, increasing the risk of fracture and separation.

- Impact Damage: High-impact loads, such as those caused by wheel flats or other defects, can initiate cracks or fractures in the flange area.

- Manufacturing Defects: In some cases, manufacturing defects or inadequate quality control may contribute to flaws or weaknesses in the flange region, increasing the susceptibility to failure.

Characteristics:

Broken Flange failures exhibit the following key characteristics:

- Flange Separation: The defining feature of a Broken Flange failure is separating a portion of the flange from the wheel, compromising its ability to guide the rail vehicle.

- Increased Occurrence: Recent data analysis has revealed a significant increase in Broken Flange failures, highlighting the need for further investigation and mitigation strategies.

- Wheel Position: Unlike VSR failures, which tend to occur more frequently on the B-end truck wheels, Broken Flange failures do not exhibit a strong bias towards a particular wheel position on the rail vehicle.

- Wear Patterns: Wheels with Broken Flange failures often exhibit advanced wear patterns, including thin flange thickness measurements.

Mitigating failures caused by broken flanges necessitates a comprehensive strategy, which involves routine inspection and upkeep, proactive wheel replacement guided by wear and impact data, and stringent quality assurance throughout the wheel manufacturing process. Furthermore, continuous research endeavors seek to enhance our comprehension of the underlying reasons and factors that lead to these failures, potentially resulting in improved methods for prevention and detection.

Plate Crack Failures

A Plate Crack failure occurs when a fracture starts in the wheel plate and can then spread into the rim area, resulting in a significant portion of the plate and rim breaking away from the wheel.

Causes and Occurrence:

Plate Crack failures, although relatively rare compared to other wheel failure modes, can occur due to various reasons, including:

- Manufacturing Defects: Imperfections or defects introduced during the manufacturing process, such as inclusions, porosity, or improper heat treatment, can create potential initiation sites for plate cracks.

- Operational Factors: Certain operational conditions, such as high-impact loads, excessive thermal stresses, or fatigue cycles, may contribute to the initiation and propagation of plate cracks.

- Material Degradation: Over time, materials can degrade due to corrosion, wear, or fatigue, increasing the susceptibility to plate cracking.

Characteristics:

Plate Crack failures exhibit the following key characteristics:

- Fracture Pattern: The defining feature of a Plate Crack failure is the fracture originating in the wheel plate and potentially extending into the rim area, resulting in the loss of a substantial portion of the wheel.

- Rarity: Plate Crack failures are generally considered rare compared to other wheel failure modes, such as VSR or Shattered Rim failures.

- Catastrophic Consequences: A Plate Crack failure can lead to a significant loss of material from the wheel, increasing the risk of catastrophic derailment.

- Diverse Causes: Plate Crack failures can arise from various causes, including manufacturing defects, operational factors, and material degradation, making their prevention and detection more challenging.

Thermal Cracking in Flange Failures

In the world of train wheel problems, thermal cracking in flanges is a significant issue that needs to be addressed. These issues, called train wheel failures, can seriously affect railway operations and safety.

Thermal cracking in flange failures occurs when transverse fatigue cracks develop from the wheel flange or tread surface. These cracks spread in a transverse direction, potentially separating a section of the wheel rim or flange.

Causes:

Thermal cracking in flanges is primarily caused by transforming beneficial compressive residual stresses in the wheel rim to detrimental tensile stresses. This stress reversal occurs due to significant tread braking, which generates localized heating and thermal gradients within the wheel.

The following factors contribute to the development of thermal cracking in flange failures:

- Tread braking: Excessive tread braking, particularly on steep grades or during extended braking events, can cause significant heating and thermal gradients within the wheel.

- Residual stress transformation: The heat generated during tread braking can transform the compressive residual stresses introduced during manufacturing in the wheel rim into tensile stresses.

- Fatigue crack initiation and propagation: The tensile stresses, combined with repeated thermal cycling, can initiate and propagate fatigue cracks, typically starting from the surface of the flange or tread.

Characteristics:

Thermal cracking in flange failures exhibits distinct characteristics that aid in identification and analysis:

- Crack location: Fatigue cracks originate at the wheel flange’s or tread’s surface and propagate in a transverse direction.

- Crack appearance: The cracks are typically straight and perpendicular to the wheel’s circumferential direction.

- Crack depth: Depending on the severity, cracks can propagate deep into the wheel rim or flange, potentially separating a portion of the wheel.

- Service conditions: These failures are more common in applications involving frequent or prolonged tread braking, such as steep grades or heavy braking conditions.

Understanding why thermal cracking causes flange failures and the mechanisms and characteristics involved is important for creating successful strategies to prevent and mitigate these occurrences. Dealing with these failures in railway wheels can improve rail safety, lower maintenance expenses, and enhance operational efficiency in the railway sector.

Thin Rim Overload Failures

Among the different kinds of failures in railway wheels, thin rim overload failures represent a unique category. If not properly identified and dealt with, these failures can present serious risks to railway operations and safety.

A thin rim overload failure happens when a part of the front rim face of the wheel breaks off due to a thin rim and a significant impact on the rail unlike other types of failures, such as vertical split rims (VSRs), thin rim overload failures are distinguished by a fracture purely caused by overload, without any fatigue or progressive cracking mechanisms.

Causes:

Thin rim overload failures are primarily caused by the following factors:

- Thin rim condition: As wheels wear over time, their thickness decreases, making them more susceptible to overload failures. Wheels with skinny rims are at a higher risk of fracturing under impact loads.

- Significant wheel-rail impact: A substantial impact force between the wheel and the rail, often resulting from track irregularities or other operational conditions, can initiate an overload failure in thin-rimmed wheels.

- Lack of residual stress or fatigue cracking: Unlike other failure modes, such as VSRs or thermal cracking, thin rim overload failures do not involve residual stress transformations or progressive fatigue crack growth.

Characteristics:

Thin rim overload failures exhibit distinct characteristics that differentiate them from other railway wheel failure modes:

- Fracture location: The fracture occurs on the front rim face, typically removing a portion of the rim material.

- Fracture appearance: The fracture surface is characterized by an overload fracture pattern without any evidence of progressive cracking or fatigue.

- Thin rim condition: The failed wheel exhibits a significantly thin rim thickness, often below the recommended minimum value.

- Impact evidence: Signs of a substantial wheel-rail impact, such as dents or deformations, may be present on the wheel tread or flange.

- Relatively low derailment risk: While thin rim overload failures can compromise wheel integrity, they are generally considered to pose a lower risk than other failure modes, such as VSRs or shattered rims.

Understanding the reasons, mechanisms, and features of thin rim overload failures is essential for creating efficient detection and maintenance plans. Dealing with these instances of railway wheel failures can enhance rail safety, minimize unexpected maintenance expenses, and improve operational efficiency in the railway sector.

Consequences of Railway Wheel Failures

Railway and train wheel failures pose significant safety risks within the rail industry. These failures may result in severe outcomes, such as derailments, property damage, and potential loss of life.

One of the main dangers associated with railway wheel failures is the sudden fracturing of wheels, which can lead to train derailments. When wheels break, it can cause a sudden loss of control, resulting in trains going off the tracks at high speeds. This situation presents a serious threat to the safety of the general public and rail workers, especially when transporting hazardous materials like crude oil or other dangerous goods.

Another impact of railway wheel failures is the possibility of causing extensive damage to the rail infrastructure. Derailed trains can significantly harm tracks, signals, and other equipment, leading to costly repairs and disruptions to rail operations. This can result in substantial financial losses for rail companies and delays in transporting goods and passengers.

Aside from the direct risks associated with derailments, railway wheel failures can also create secondary hazards. For example, a derailed train carrying hazardous materials could lead to spills or releases, posing environmental risks and potential health hazards to nearby communities.

To mitigate these risks, rail companies and regulatory authorities have put in place various measures, such as regular inspections, maintenance protocols, and guidelines for wheel replacement. However, railway wheel failures continue to occur despite these efforts, emphasizing the need for ongoing research, improved detection methods, and enhanced prevention strategies.

Conclusion

Railway and train wheel failures pose significant risks to the safety and efficiency of rail operations. As highlighted throughout this article, various wheel failures exist, each with unique underlying causes and characteristics. From vertical split rims (VSRs) and shattered rims to broken flanges, plate cracks, thermal cracking, and thin rim overload failures, these issues demand comprehensive understanding and proactive mitigation strategies.

Addressing railway wheel failures is crucial for preventing catastrophic derailments, minimizing environmental impacts, and ensuring the reliable transportation of goods and passengers. Consequences such as property damage, loss of life, and substantial financial losses underscore the importance of prioritizing safety in the rail industry.

If defect is limited to tread/flange wear and profile deviation without deep cracks or subsurface damage, turning or reprofiling is cost-effective; once cracks extend into the rim body or the material shows fatigue or thermal damage, replacement is safer despite higher cost.

Key metrics include rate of wheel-rail impacts (from WILD), frequency of high heat in bearings, wheel profile wear rate over time, number of wheel flats, occurrence of shallow cracks from NDT, and service operating environment (grade, braking frequency, load).

Deviations in wheel tread geometry (flange thickness, wear, hollow tread) alter contact stress distribution, increasing Hertzian stress peaks; poor equivalent conicity accelerates fatigue, promoting VSRs and shattered rims.