Wheel and Rail Profile Measuring Device (WRPM)

With a perfect combination of technology and efficiency, ADOR’s in-track wheel measuring system offers a comprehensive inspection.

OVERVIEW

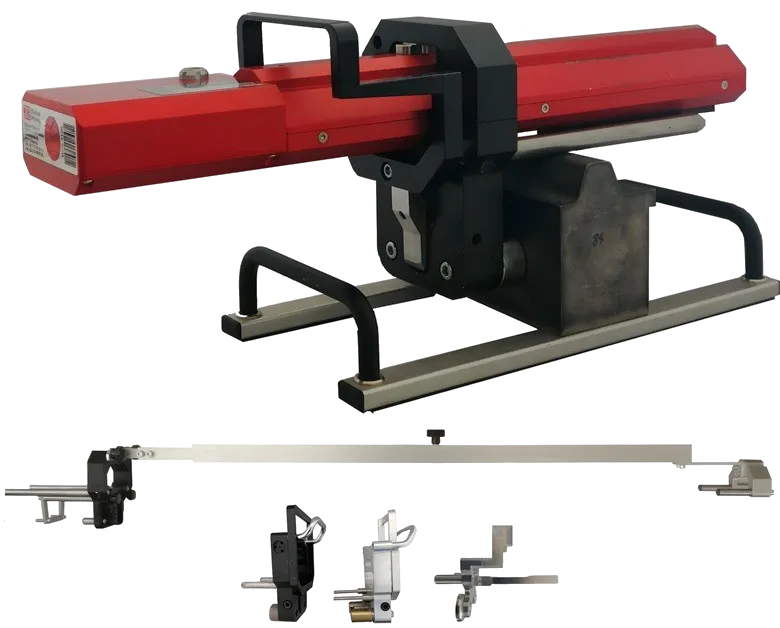

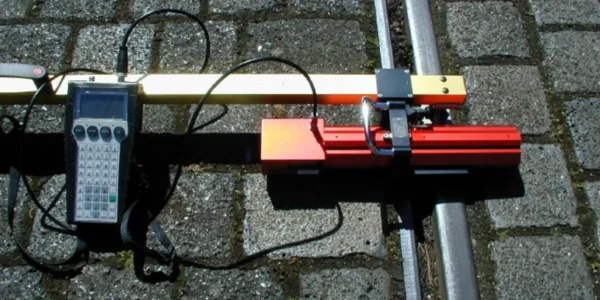

ADOR’s Wheel and Rail Profile Measuring Device (WRPM) is a portable, laser-based solution for accurately inspecting both wheel and rail profiles. Designed for versatility, the system allows quick setup using magnetic holders for wheel measurement and a track gauge bar for rail analysis.

This compact device captures key parameters such as wheel diameter, flange height/thickness, QR/W/D values, and rail head wear, with a measurement accuracy of up to 0.05 mm. Ideal for depots, workshops, and field inspections, the WRPM enables efficient, real-time monitoring of geometry, wear history, and profile deviations, ensuring safe and reliable rail operations.

Some parameters that ADOR’s portable rail profile measurement system can inspect are as follows:

- Rail Head Profile

- Track Gauge

- Wear History

- Nominal vs. Actual Profile Comparison

- Wheel Diameter

- Flange Height (SH)

- QR Dimension

technical SPECIFICATIONS

The in-track wheel profile inspection system is engineered for high-precision, contactless measurement of railway wheels under operational conditions. Installed directly within the track structure, it delivers consistent and accurate results for multiple wheel parameters as trains pass through at controlled speeds. The system is designed for indoor and outdoor use and supports various wheel profiles, vehicle types, and axle configurations.

The core technical specifications are listed below. For details on full integration and software compatibility, please refer to the catalog.

| Measuring range: 48–60 mm |

| Resolution: 0.05 mm – 0.1 mm |

| Vertical movement: 150–160 mm (customizable) |

| Output: RS 232 or Bluetooth |

| Laser wavelength: 660 nm |

| Operating temperature: –5°C to +30°C, non-condensing |

Gallery

Catalog

Please fill out the form to download the catalog:

Related Products

In-Track Wheel Measuring System

Integrated into the track

Eddy Current Flaw Detectors

Mechanized scanning device

Ultrasonic Flaw Detector

Continuous mechanized testing

Wheel Diameter Measuring Device

Designed to accurately measure wheel diameter

Contact Line Measuring System

Contact line height and stagger

FAQS

What is the typical scan time per measurement?

Approximately 5 seconds per scan, allowing fast throughput during multi-vehicle inspections.

How is data stored and used?

Measurement results can be saved via USB or Bluetooth and processed in compatible software for tracking, reporting, and long-term trend analysis.

1. How can I get more information about your in-track wheel measuring systems?

Contact us for detailed technical documentation or tailored solutions to suit your project needs.

What is the scope of your work?

Our scope of work encompasses Canada and extends globally, offering tailored solutions for infrastructural and industrial needs.

Does the system require calibration or adjustment before each use?

The system is factory-calibrated and designed for plug-and-play operation. Periodic calibration checks may be performed as part of your internal QA processes.

Portable Wheel and Rail Profile Measuring Device: The Compact Tool for Accurate Rail Diagnostics

Railways demand precision. Whether it’s ensuring the smooth interaction between wheels and rails or preventing derailments and vibration, routine measurement of wear and geometry is essential. Traditionally, this meant large fixed systems or manual gauges—but now, rail technicians rely on one compact, laser-based solution: the portable wheel and rail profile measuring device.

This mobile system is engineered for ease of use, field portability, and micron-level accuracy. It’s fast, adaptable, and perfect for depots, rolling stock workshops, and light rail networks alike.

Let’s explore why this dual-use portable device is becoming the gold standard in railway maintenance operations.

What Is a Portable Wheel and Rail Profile Measuring Device?

A portable wheel and rail profile measuring device is a laser-based tool used to inspect the geometric dimensions of both wheels and rails. Unlike in-track or stationary systems, this handheld system can be easily transported and operated by a single technician.

The same unit can be:

- Mounted on a rail wheel using magnetic holders for wheel profile measurement

- Mounted on a track gauge bar to scan the rail head and track geometry

This versatility makes it ideal for inspections during maintenance, post-reprofiling validation, or emergency geometry checks on-site.

How Does a Mobile Wheel and Rail Profile Measuring System Work?

Using laser triangulation and high-resolution scanning, the device captures key profile data in under 5 seconds. Its integrated sensor moves vertically over the surface, collecting measurements with a resolution of up to 0.05 mm.

Key features:

- Magnet-based mounting for fast setup on wheels

- Gauge bar attachment for rail profile scanning

- Laser class 3R for safety and performance

- Bluetooth or USB data output, depending onthe model

- Onboard software or external evaluation tools (e.g., WheelPro)

Whether on a workshop floor or trackside, this mobile tool delivers reliable results without interrupting operations.

What Parameters Can Be Measured by WRPM?

The device captures critical safety and performance indicators for both wheel and rail profiles:

Wheel Profile Parameters:

- Average wheel diameter

- Flange height (SH) and thickness (SD)

- QR, W, and D dimensions

- Flank angle

- Runout (roundness)

- Wear history

- Difference between paired wheel diameters

Rail Profile Parameters:

- Rail head profile acquisition

- Track gauge and track width

- Hollow running

- Runout and rail wear

- Nominal vs. actual profile comparison

This makes it suitable for both light rail systems and heavy rolling stock inspection programs.

Why Choose a Handheld Rail Profile Measurement Tool?

Here are the key advantages of handheld and mobile tools over traditional setups:

- Mobility: Lightweight (approx. 1.5 kg) and easy to transport between vehicles or sites

- Speed: Measures profiles in seconds without needing to lift or disassemble wheelsets

- Versatility: One device for both rail and wheel profiles

- Usability: Simple operation by a single technician with minimal setup

- Data integration: Output compatible with databases and maintenance planning tools

Unlike bulky in-track systems, a handheld rail profile measurement tool is cost-effective and accessible for smaller operators and depot teams.

Common Use Cases in the Railway Industry

- Depot entry/exit inspections

- Wheelset reprofiling validation

- Field-based track gauge checks

- Light rail and tram wheel monitoring

- Post-incident investigations

Routine geometry data logging

The tool is especially valued in urban transit systems and regional rail, where flexibility and speed are key.

How Accurate Is a Portable Wheel Profile Measuring Device?

The WRPM is designed to deliver high accuracy despite its compact size. Based on the latest model specifications:

- Measuring range: 48–60 mm

- Resolution: 0.05 mm to 0.1 mm

- Vertical movement: 150–160 mm

- Scan duration: ~5 seconds

- Operating temperature: –5°C to +30°C

- Laser wavelength: 660 nm

These specs match or exceed most stationary systems, making it ideal for professional-grade inspections in the field.

Who Should Use WRPM?

- Maintenance Technicians

- Wheelset Reprofiling Operators

- Fleet Maintenance Managers

- Depot Teams

- Track Inspectors

It’s especially valuable in environments where multiple vehicle types operate or when space and access constraints make fixed systems impractical.

Can the Data Be Saved and Analyzed?

Yes. The device supports Bluetooth or USB data output and integrates with evaluation and archiving software. Results can be saved, visualized, and compared to historical measurements for:

- Wear progression tracking

- Flange growth patterns

- Grinding strategy planning

- Regulatory compliance logs

This supports a move toward predictive maintenance and improved asset lifecycle management.

Conclusion

A portable wheel and rail profile measuring device is more than just a tool—it’s an investment in safety, efficiency, and reliability. By combining wheel and rail inspection in one compact system, rail operators can save time, reduce errors, and maintain better control over vehicle and track health.

Whether you’re a metro operator, a national rail maintenance contractor, or an engineer on the move, this mobile laser-based system delivers everything you need in a field-ready format.