Mooring buoys are crucial for securely anchoring vessels in busy harbors or open waters without traditional anchors. This blog post explores everything you need to know about mooring buoys, including what they are and the available types. You’ll learn about the key parts of a mooring buoy, such as the buoy, the mooring chain, and the seabed anchor, which all work together to hold a vessel safely in place. We also explain how these buoys are anchored and the meaning behind their color codes, which help mariners navigate safely. Additionally, we’ll cover important considerations when choosing the right buoy, including size, durability, and weight capacity.

Need a durable, low-maintenance mooring buoy? Explore our full line of “marine buoys” built for demanding mooring applications.

What Is a Mooring Buoy?

A mooring buoy is a floating device to secure vessels in specific locations, allowing boats to tie up without deploying their anchors. Unlike navigational buoys, which mark channels, hazards, or safe water, mooring buoys serve as fixed points for boats to attach to, often found in marinas, harbors, or designated mooring fields. These buoys are anchored to the seabed using a chain or rope connected to a heavy anchor, which ensures the buoy stays in place.

Mooring buoys help reduce wear on boats’ anchoring gear and prevent environmental damage, as they eliminate the need for vessels to repeatedly drop anchors, which can disturb marine life or the seabed. Their primary function is to provide a reliable and safe method for vessels to remain stationary without traditional anchoring methods.

What is the Purpose of a Mooring Buoy?

Mooring buoys are strategically placed in harbors, marinas, or offshore locations, providing a reliable point for vessels to anchor without traditional methods. They minimize environmental impact, reduce wear and tear on boats’ anchoring gear, and enhance safety by keeping vessels securely in place and avoiding overcrowding in busy waterways.

See also: “Cautionary Buoys with a Comprehensive Guide“

Types of Mooring Buoys

Mooring buoys come in various designs to accommodate different needs. One of the most used types is the Single-Point Mooring Buoy (SPM). This buoy is anchored at a single point on the seabed and is ideal for large vessels, such as tankers, that must load or unload cargo while remaining stationary. The vessel is attached to the buoy via a single mooring line or chain, allowing it to rotate freely with changes in wind and current directions, making it highly versatile in open water.

Multiple-Point Mooring Buoys, on the other hand, provide a more stable and secure mooring system. In this setup, several buoys are anchored at different points and connected by mooring lines to create a mooring field. This system is often used in marinas or harbors, where multiple vessels must be securely moored in a fixed area.

Other common mooring buoys include mooring balls, used for smaller vessels in shallow waters, and temporary mooring buoys, designed for short-term docking in busy areas. Each type serves a distinct purpose depending on the vessel size and mooring conditions.

Main Parts of a Mooring Buoy

A mooring buoy has several key components that ensure its functionality and durability. Each part plays a crucial role in securing vessels while minimizing environmental impact.

Buoy

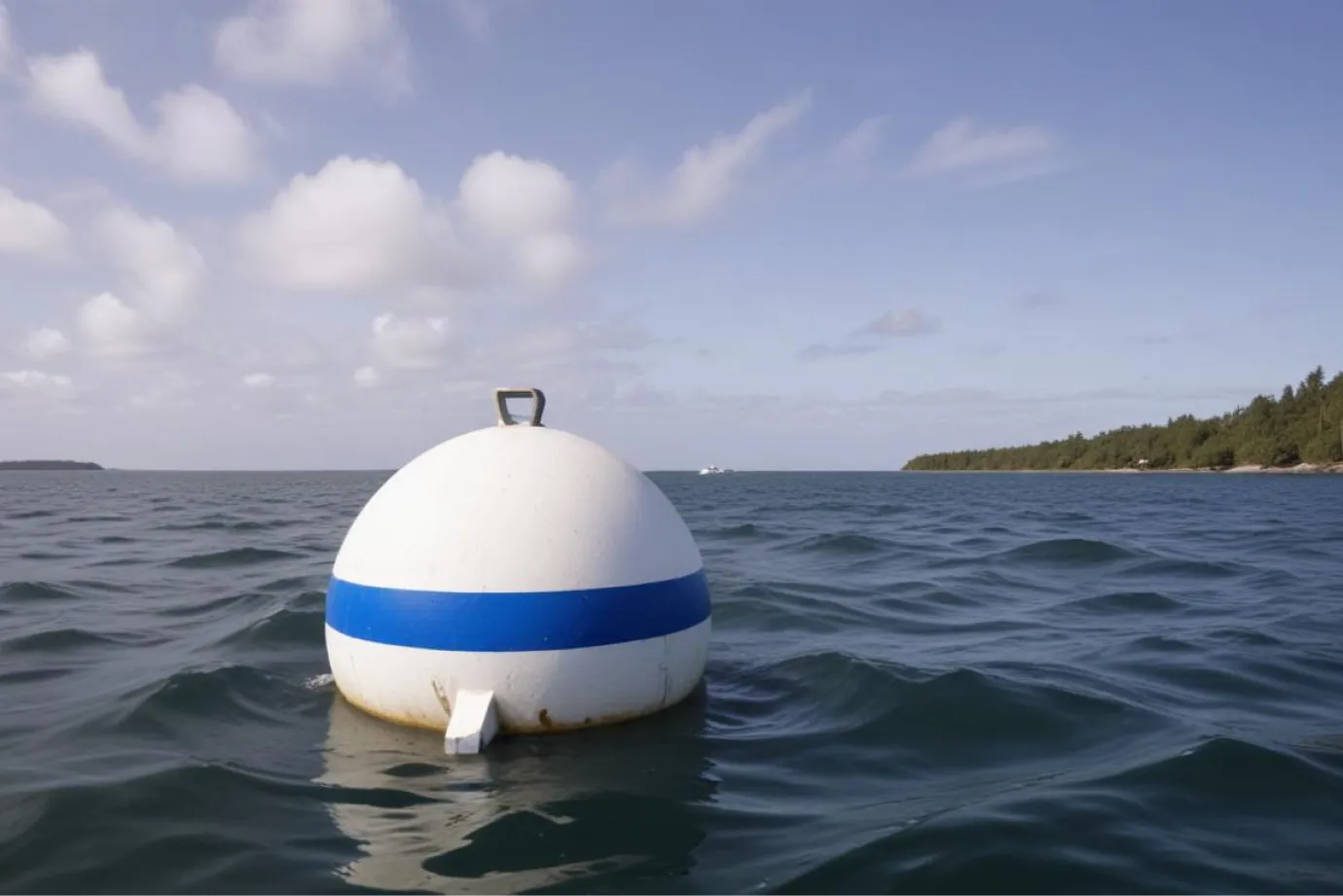

The buoy itself is the most visible part of the system. It floats on the water’s surface, providing buoyancy and visibility to the entire structure. Made from durable materials like foam-filled plastic, polyethylene, or steel, buoys are designed to withstand harsh marine environments. The buoy’s shape can vary, but spherical or cylindrical designs are most common. Its primary function is to keep the mooring system afloat while visible to mariners. Additionally, the buoy is often brightly colored (white with a blue stripe, for example) to enhance visibility and help boaters locate it easily.

Mooring Chain or Line

This component connects the buoy to the seabed anchor. The choice between using a chain or a rope depends on the type of water and the vessel size. Chains, usually made from galvanized steel, are more durable and corrosion-resistant, making them suitable for deeper waters and larger vessels. Ropes, often made of nylon or polyester, are used for smaller boats in shallow waters. The mooring chain or line is critical in absorbing the shock and tension caused by the boat’s movement due to wind and current, ensuring the buoy remains stable.

Seabed Anchor

The seabed anchor holds the entire mooring system in place. There are various types of anchors, with mushroom anchors and concrete blocks being the most common. Mushroom anchors are designed for the soft seabed, where they can dig into the sand or mud, creating a secure hold. These anchors are ideal for vessels in areas with significant water movement, such as tidal regions. Concrete blocks are another option for smaller or temporary mooring buoys. These anchors rely on their heavy weight to remain stable on the seabed. The anchor choice depends on factors such as water depth, seabed type, and the size of the vessels that will use the buoy.

Attachment Hardware

The attachment hardware consists of shackles, swivels, and other connectors that secure the vessel to the buoy. Shackles connect the mooring chain to both the buoy and the anchor. Swivels, however, allow the buoy to rotate with the vessel’s movement, preventing the mooring line from tying. This hardware is usually made from corrosion-resistant materials such as stainless steel, ensuring longevity in marine conditions. Proper attachment hardware is essential for safely securing vessels, especially in areas with strong currents or changing tides.

Identification Markings

Mooring buoys are often marked with unique identifiers to assist mariners in recognizing their purpose or ownership. These markings can include numbers, letters, or logos, which help identify the buoy’s function for general mooring, private use, or specific marine operations. Additionally, the colors of the buoy are often regulated by maritime authorities. For example, a standard mooring buoy may be white with a horizontal blue band, while other colors, such as yellow or orange, may indicate special purposes or restricted areas. These markings are critical for ensuring boaters use the correct buoy and follow any associated local regulations.

How Does a Mooring Buoy Work?

A mooring buoy provides a fixed point for vessels to anchor safely, preventing the need for dropping a traditional anchor. Here’s a step-by-step guide to the process:

- Approach the Buoy: The vessel approaches the mooring buoy slowly and from downwind or against the current. This allows for better control and positioning while maneuvering toward the buoy.

- Prepare the Line: The crew prepares a mooring line or rope, typically attached to a cleat on the vessel, which will be used to secure the boat to the buoy.

- Pick-Up Line: Some buoys have a pick-up line (a smaller floating line connected to the buoy). The crew uses a boat hook to grab and pull the pick-up line aboard.

- Securing the Vessel: The pick-up line is attached to the vessel’s bow cleat. If there is no pick-up line, the mooring line from the boat is threaded through the buoy’s attachment ring, often with the help of a hook.

- Final Adjustments: Once the vessel is attached, the line is adjusted to the correct tension to ensure the boat remains secure. The buoy absorbs the forces of wind, waves, and current, keeping the boat in place while allowing it to pivot around the buoy as conditions change.

This system allows boats to stay securely moored without frequent adjustments or concerns about dragging an anchor, making it both convenient and environmentally friendly.

How Are Mooring Buoys Anchored?

Mooring buoys are anchored to the seabed using various methods depending on the water depth, seabed conditions, and the size of the vessels intended to support. One common method is mushroom anchors, which are ideal for soft seabeds like mud or sand. These anchors dig into the seabed, creating a strong hold over time as they bury deeper with pressure. Another option is deadweight anchors, often made from concrete or large blocks, which rely on sheer weight to keep the buoy in place. These are commonly used in shallower waters or where the seabed is rocky.

Helix anchors may be used for deeper waters or locations with stronger currents. These are screwed into the seabed, providing a very secure hold. The mooring chain or line connects the buoy to the anchor, allowing the buoy to remain stable on the water’s surface while firmly attached to the anchor below.

What Do the Colors on a Mooring Buoy Mean?

Mooring buoys are color-coded to provide clear information to mariners regarding their use and ensure water safety. The most common color combination for mooring buoys is white with a blue horizontal band. This combination signals that the buoy is designated for mooring purposes, meaning boaters can securely tie it up. These buoys are typically found in designated mooring areas within marinas, harbors, or offshore mooring fields.

In addition to the standard mooring buoy, other color codes may be used for different purposes. For example, yellow buoys are often used for special purposes, such as marking restricted areas or indicating caution zones. Red and green buoys are primarily used in navigation to mark the edges of channels or to indicate safe passage, but they are not typically associated with mooring.

Color coding helps mariners quickly identify the function of each buoy, reducing confusion and improving safety. The specific color patterns may vary slightly depending on local maritime regulations, but the white and blue pattern for mooring buoys is widely recognized internationally. This system ensures that mariners understand the purpose of the buoy they encounter and can act accordingly, whether they are mooring their vessel or navigating safely through a waterway.

Mooring Buoy Sizes

When selecting the right size of a mooring buoy, several factors should be considered to ensure safety and functionality. One key aspect is vessel size. Larger boats require larger buoys with greater buoyancy to support the weight and forces exerted by the boat. A buoy that is too small may not have enough floatation capacity, leading to instability or submersion under heavy loads.

Water conditions also play an important role. Larger and more robust buoys are recommended in areas with strong currents, tides, or winds, as they can withstand greater stress. Buoys in these environments may also need more buoyancy to handle the additional forces caused by environmental factors. Conversely, for calm and protected waters, smaller buoys might suffice.

Another consideration is the weight of the mooring system itself, including the chain or line and the anchor. The buoy must be able to support the vessel and the mooring hardware. It’s essential to ensure that the buoy’s buoyancy exceeds the total weight it will need to carry.

Finally, regulatory requirements and standards should be reviewed, as different marinas or regions may have specific guidelines on mooring buoy sizes based on vessel categories. By considering these factors—vessel size, water conditions, mooring weight, and regulations—you can select the right buoy size to secure mooring and prevent potential risks.

Key Considerations When Choosing a Mooring Buoy

When choosing a mooring buoy, several key considerations ensure that it will meet the needs of your vessel and the environment. One of the most important factors is durability. The buoy should be made of high-quality, long-lasting materials like foam-filled plastic or polyethylene, which is resistant to harsh marine conditions, UV rays, and corrosion. Durability ensures the buoy can handle prolonged exposure to saltwater, sunlight, and constant friction from mooring lines.

Weight capacity is another crucial element. The buoy must have sufficient buoyancy to support the weight of the vessel and the mooring system, including chains, ropes, and anchors. Choosing a buoy with inadequate capacity can lead to instability or even failure during rough seas or high winds. A buoy with a higher weight tolerance is necessary for larger vessels or more exposed environments.

Environmental conditions like water depth, tidal ranges, and wind strength should also guide your selection. A more robust and larger buoy may be required in areas with strong currents or frequent storms to ensure the vessel remains securely moored. Additionally, a longer mooring line and a larger buoy might be necessary in deeper waters to accommodate fluctuations in water level due to tides.

Finally, review any local regulations that may specify requirements for mooring buoy size, weight capacity, and placement. Choosing the right buoy means balancing these factors for safe and effective mooring in your specific setting.

The typical system includes:

– Buoy: Buoyant body—often made from foam-filled plastic or polyethylene—for visibility and flotation.

– Chain or Line: A durable connector (galvanized steel chain or synthetic rope) linking the buoy to the anchor to manage tension and vessel movement.

– Seabed Anchor: Heavy-duty anchors like mushroom, deadweight, or screw variants, chosen based on seabed type and depth.

– Attachment Hardware & Markings: These include shackles, swivels for movement, and distinct identifiers or color bands (commonly white with a blue stripe) for clear identification.

1- Approach carefully, moving slowly with the wind or current to maintain control.

2- Use the pick-up line (if available) to hook the buoy and bring the line aboard.

3- Secure and adjust the line at the cleat to ensure tautness; the swivel allows the vessel to pivot naturally as conditions change.

Standardized markings (e.g., white with a blue band) help boaters quickly identify legitimate mooring points, avoiding confusion with navigation markers and ensuring safe, regulated use.

ADOR Tech provides high-performance mooring buoys featuring:

1- A buoyancy capacity of 110 liters using closed-cell PU foam

2- Sturdy galvanized lifting eyes and an internal reinforced core

3- Load capacities up to 80 kg, available in red, green, or yellow, meeting IALA E‑108 compliance standards