Eddy Current Flaw Detectors

Ensure fast, accurate, and non-destructive rail inspection with our Eddy Current Flaw Detector. Designed to detect cracks, weld defects, and surface flaws, it offers high-speed, portable testing for railway components, maximizing safety, reliability, and operational efficiency.

OVERVIEW

ADOR provides sophisticated eddy current flaw detectors designed to automatically test and measure various railway components using cutting-edge technology. Available in portable, single-rail, and double-rail configurations, our devices offer high-speed, high-precision inspection across both surface and sub-surface defect zones.

Equipped with multi-frequency capabilities and high-resolution sensors, the system ensures reliable detection of cracks, corrosion, and weld flaws—without interrupting operations. The intuitive interface, robust construction, and real-time data visualization make it ideal for both in-field inspections and structured maintenance programs.

Key Applications:

- Crack Detection

- Welding Quality Inspection

- Rail Track and Track Switch Monitoring

- Surface and Subsurface Defect Evaluation

- Detection of corrosion pits and grinding burns

- Preventive maintenance and asset integrity checks

ModelS

ETS2-73

ETS2-77

OKOSCAN 73HS

SMARTSCAN

EDDYCON C

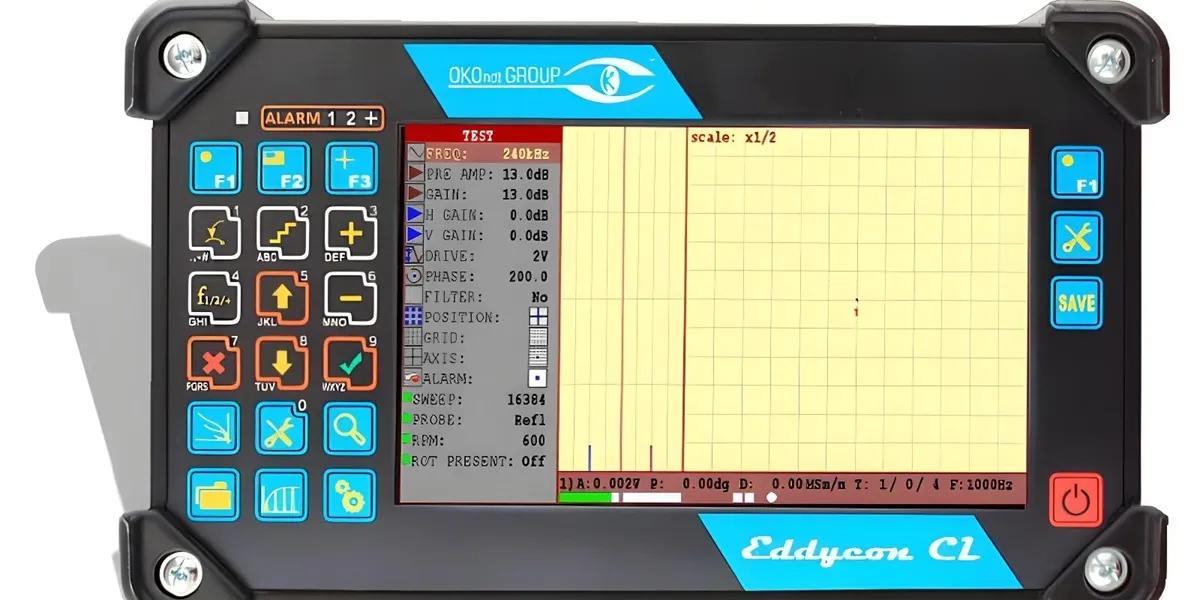

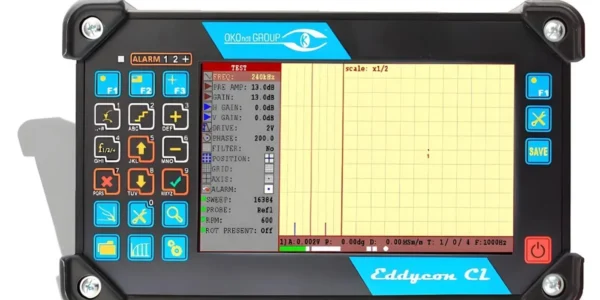

EDDYCON CL

EDDYCON D

technical SPECIFICATIONS

Our Eddy Current Flaw Detector is engineered for precise, non-destructive testing of rail components under real-world operating conditions. Designed with portability, speed, and accuracy in mind, it supports advanced detection of surface and subsurface flaws using electromagnetic induction.

The general technical specifications are listed below. For detailed performance capabilities and optional configurations, please download the catalog at the bottom of the page.

| Frequency Range: 10 Hz to 16 MHz (Fixed 200 kHz for high-speed rail) |

| Gain Range: Up to 70 dB + 30 dB additional gain |

| Probe Types: Single coil, Reflection, Bridge, Pencil-type (wheel scanners) |

| Inspection Speed: Manual scan to 2 m/s (portable & double rail), up to 40 km/h (high-speed) |

| Power Supply: 12V Li-ion battery or 110–240V AC depending on system type |

| Data Storage: MicroSD, USB, internal PC database depending on configuration |

Gallery

Catalog

Please fill out the form to download the catalog:

Related Products

Ultrasonic Flaw Detector

Continuous mechanized testing

Rail Profile Measuring Device

Mobile Device

Wheel Force Diagnostic System

Installed in the track without any changes

Ultrasonic Thickness Gauges

Provides accurate thickness measuring

FAQS

What is the minimum detectable flaw size?

Depending on the model and probe type, flaws as small as 0.002 mm in width and 0.05 mm in depth can be detected.

Is calibration required before every use?

While our systems are designed for ease of use, regular calibration using reference blocks ensures optimal accuracy—especially for critical applications.

How can I get more information?

Contact us for detailed technical documentation or tailored solutions to suit your project needs.

What is the scope of your work?

Our scope of work encompasses Canada and extends globally, offering tailored solutions for infrastructural and industrial needs.

Can we integrate this with our existing inspection workflow?

Absolutely. All devices support PC communication and come with software for data logging, analysis, and export.

What Is an Eddy Current Flaw Detector?

An Eddy Current Flaw Detector is a highly specialized non-destructive testing (NDT) device used to detect cracks, corrosion, and surface defects in conductive materials. In the railway industry, it is primarily applied to inspect rail tracks, welds, switches, wheels, and other structural components to prevent failure, enhance safety, and ensure compliance with maintenance standards.

Using the principle of electromagnetic induction, the system induces eddy currents in the material under test. If there is a flaw—like a crack or a void—it disturbs the current’s flow, and the system detects these disturbances, allowing for precise identification of surface and subsurface irregularities.

Why Use an Eddy Current Crack Detector for Railway Infrastructure?

Railway infrastructure operates under constant mechanical and environmental stress. Cracks in rails, poorly fused welds, or unnoticed corrosion can quickly escalate into major hazards. An Eddy Current Crack Detector offers a fast, contactless solution to inspect such defects without halting railway operations.

It is especially effective for:

- Surface fatigue cracks (e.g., headchecks)

- Subsurface welding flaws

- Quench cracks on the gauge corners

- Early-stage corrosion pits

- Post-grinding inspection

By incorporating high-sensitivity eddy current technology, operators can locate and monitor flaws before they evolve into dangerous conditions—thus improving asset reliability and reducing repair costs.

Key Applications of Eddy Current Testing Instruments

Our Eddy Current Testing Instruments are engineered for both portable and automated inspections, and they are widely used in:

Track switch and joint inspection

Crack detection on rail heads and gauge corners

Welding quality control

Wheelset and axle box inspection

Aircraft wheel flaw detection (SMARTSCAN series)

High-speed inline inspection systems (OKOSCAN 73HS)

These instruments are versatile, supporting both manual and automated testing operations depending on the environment and defect type.

Types of Eddy Current Flaw Detectors We Offer

At ADOR, we provide a comprehensive range of Eddy Current Flaw Detectors, each tailored for specific use cases:

1. Portable Eddy Current Surface Scanner

Ideal for maintenance crews and in-field inspections. Compact and lightweight, these models (such as Eddycon C/CL) can detect cracks with a depth as small as 0.05 mm. Features include a dual-frequency mode, user-friendly interface, and up to 10 hours of battery life.

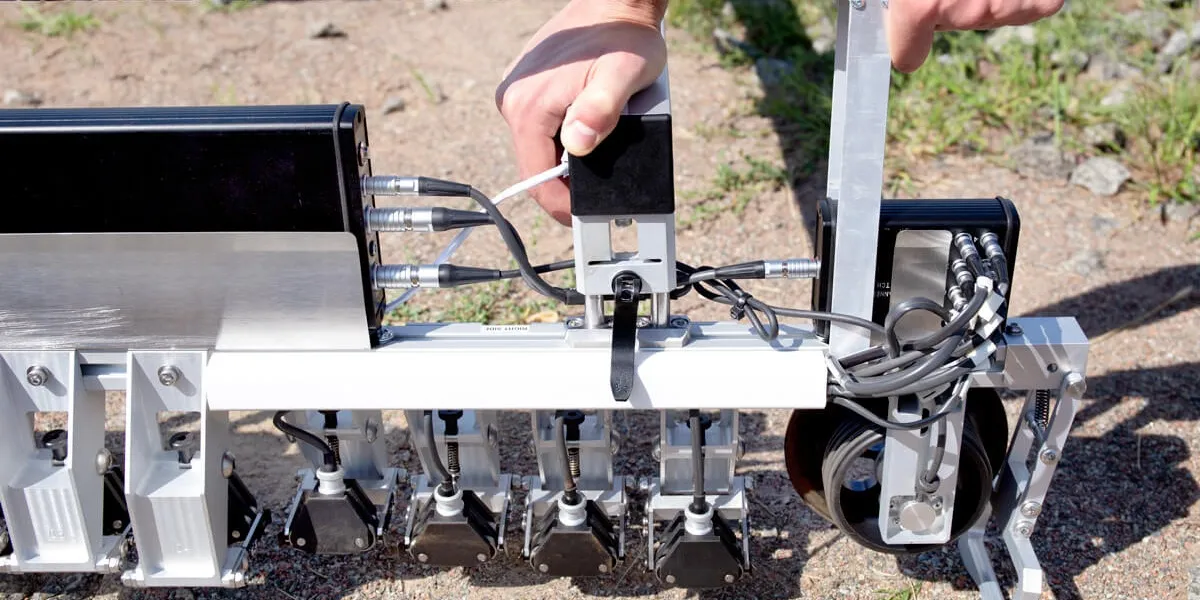

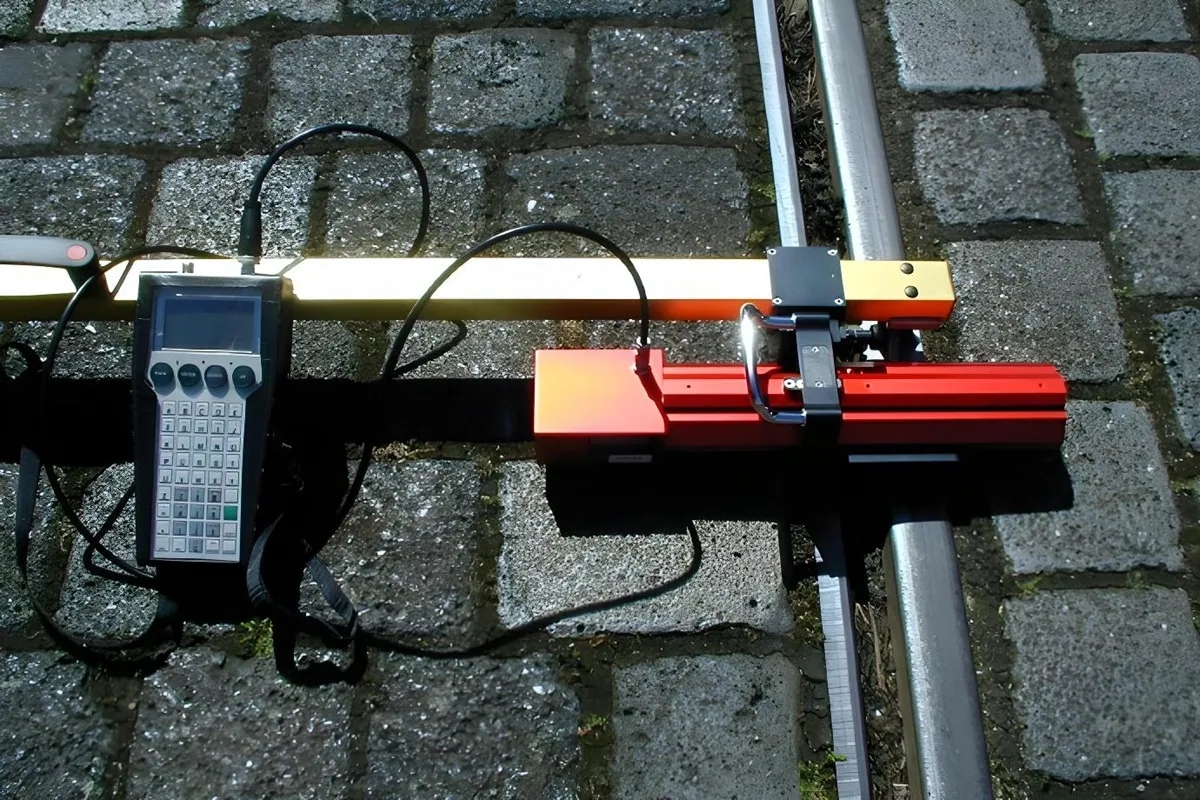

2. Eddy Current Double Rail Detector (ETS2-73)

This mechanized scanning device inspects both rails simultaneously with 16 ECPs (8 per rail). It is perfect for routine inspections and detects critical flaws in the gauge corner and running surface—especially useful for national rail operators.

3. Eddy Current Single Rail Detector (ETS2-77)

Built for selective and local inspections on one rail. Highly adaptable to different rail profiles and switch zones.

4. Eddy Current Surface Scanner for Wheels (SMARTSCAN)

This semi-automated or fully automated system is optimized for aircraft and rail wheels. It inspects cylindrical and radial transitions with high repeatability and speed (up to 23 m/s), using pencil-type probes.

5. High-Speed Eddy Current Testing System (OKOSCAN 73HS)

Designed for automated rail track inspection at speeds up to 40 km/h. Equipped with 16 ECPs and dual Eddycon D detectors, this solution enables real-time monitoring and full-coverage flaw detection in both rolling surfaces and gauge corners.

Key Advantages of Eddy Current Inspection Devices

Eddy Current Testing is trusted across industries due to its powerful set of benefits:

Non-destructive: Inspections can be performed without altering or damaging the component.

No need for surface contact: Inspections can be conducted even through paint or coatings.

Instant feedback: Results are visualized in real-time and can be stored for further analysis.

Portable and Automated options: From hand-held units to high-speed mechanized systems.

High accuracy: Detects flaws as small as 0.002 mm in width.

Flexible probe configurations: Including bridge-type, reflection-type, single coil, and pencil probes.

What Makes Our Eddy Current Inspection Devices Different?

At ADOR, we combine world-class technology with industry-specific customization. Our flaw detectors conform to standards such as ISO 15548-1, EN 16729-2, and UIC Code 712 R, and are used globally by rail operators, aircraft maintenance crews, and heavy industry clients.

We provide:

Custom calibration per application

Software with automatic defect classification

Modular configurations for multi-channel systems

Real-time data processing and visualization