Laser-Based Wheel Force Diagnostic System (Lasca)

Detect wheel-rail forces and evaluate tread damage diagnostics with ADOR’s innovative monitoring system (Lasca).

OVERVIEW

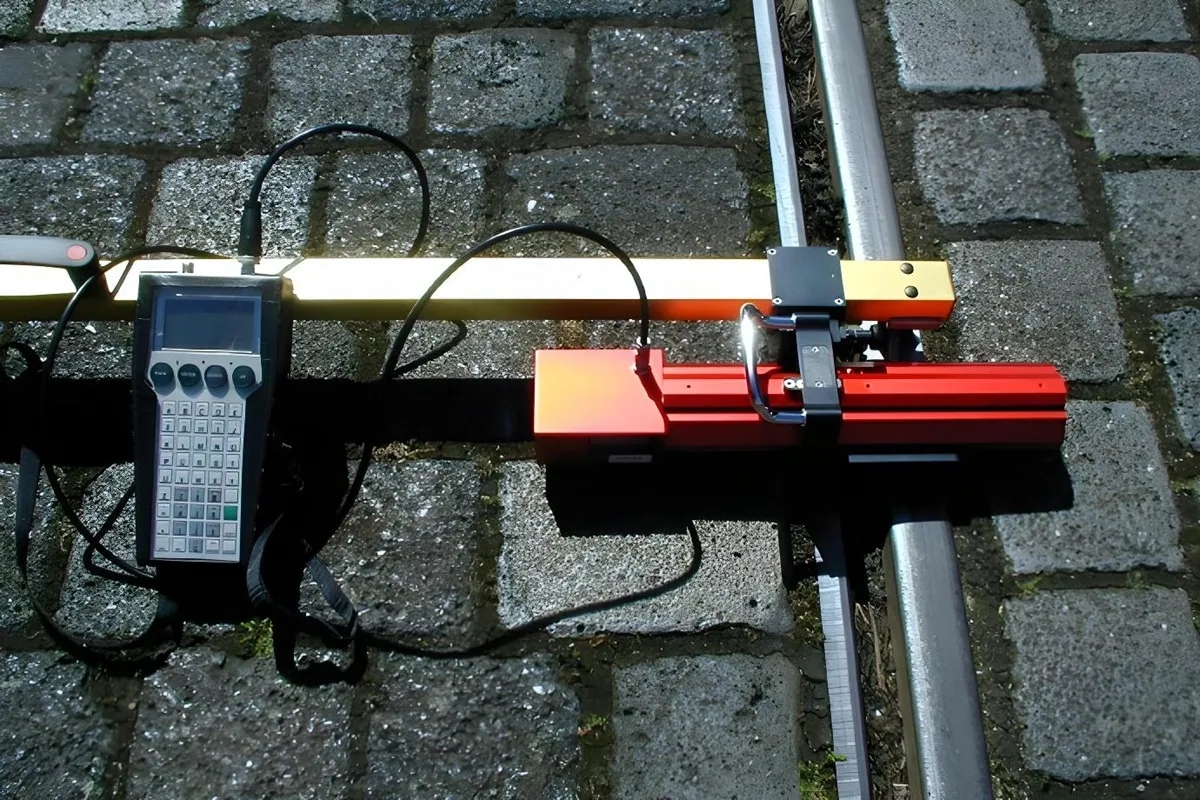

Our exclusive and innovative solution is a laser-based wheel force diagnostic system designed to accurately measure wheel-rail interaction forces and assess wheel tread integrity under real operating conditions. Installed within natural track gaps, this non-intrusive technology operates without requiring structural modifications, using patented sensors to detect rail deformation caused by passing wheels.

This self-monitoring and TÜV-certified platform continuously evaluates each wheel, automatically capturing critical performance data in real time. By analyzing the rail’s response to dynamic loads, the Lasca identifies subtle wheel defects that traditional inspections often miss.

Key parameters monitored include:

- Wheel load distribution and imbalance

- Wheel flats (both isolated and repeating)

- Polygonal wear (periodic geometry distortions)

- Out-of-roundness and eccentricity

- Random (stochastic) tread irregularities

- Load shifts linked to tight bogies or improper bogie alignment

This laser-based measurement solution also offers integrated train and vehicle identification, graphical reporting of rail deflections, and compatibility with central monitoring platforms. Supporting operational speeds of up to 400 km/h, it delivers high-resolution insights that empower infrastructure operators to move from reactive to condition-based maintenance strategies.

technical SPECIFICATIONS

The Laser-Based Wheel Force Diagnostic System is engineered for in-track, high-speed evaluation of wheel-rail interaction and tread-related defects. Built for durability and precision, it operates without modifying the track structure and provides real-time data for advanced fleet and infrastructure monitoring.

The key technical specifications are listed below. For integration options and system configurations, please download the catalog at the bottom of the page.

| Number of measuring points: 2 × 6 (in sleeper compartments) |

| Measuring distance / Settlement wheel: 4000 mm |

| Wheel diameter range: 250 mm – 1273 mm |

| Sensor range: 10 kg – 100 tons |

| Resolution: 100 nm (0.0001 mm) |

Gallery

Catalog

Please fill out the form to download the catalog:

Related Products

Rail Profile Measuring Device

Mobile Device

Eddy Current Flaw Detectors

Mechanized scanning device

Ultrasonic Flaw Detector

Continuous mechanized testing

Contact wire wear measuring

Continuously records the wear

FAQS

What is the main advantage of a laser-based wheel monitoring system?

It allows non-contact, real-time evaluation of wheel forces and defects under operational speeds (up to 300 km/h or more) without interrupting service.

Can Lasca detect random or non-patterned tread damage?

Yes. Unlike traditional methods, laser sensors can differentiate between periodic defects like polygons and stochastic irregularities such as flat spots or debris impacts.

How do I get more information or request a quotation?

You can contact us directly through the website or email us at (info@adortech.com).

What is the scope of your work?

Our scope of work encompasses Canada and extends globally, offering tailored solutions for infrastructural and industrial needs.

Is this technology suitable for freight or light rail networks?

Absolutely. It supports a wide range of applications, including freight wagons, metro trains, trams, and high-speed rail.

Laser-Based Wheel Force Diagnostic Systems: A New Standard in Rail Monitoring

Railway safety and maintenance have evolved drastically over the past few decades. With trains running at higher speeds and bearing heavier loads, the need for precise, real-time monitoring of wheel performance has never been more critical. Enter the laser-based wheel force diagnostic system—a game-changing innovation that enables non-contact, continuous evaluation of wheel-rail dynamics.

This article explores how this technology works, what defects it detects, and why rail operators worldwide are adopting wheel force monitoring systems as a core part of their asset management strategy.

What Is a Wheel Force Diagnostic System?

A wheel force diagnostic system is an advanced, rail-mounted technology that measures the forces a train’s wheels exert on the track while in motion. Unlike traditional inspection methods that require downtime or manual intervention, this system uses laser sensors and high-resolution electronics embedded in the track structure to detect wheel behavior dynamically—at operational speeds of up to 300 km/h or more.

By analyzing the deflection of the rail caused by each passing wheel, the system accurately determines:

- The dynamic wheel load

- Force imbalances between axles

- Signs of irregular tread geometry

- Indications of mechanical issues, such as tight bogies or suspension faults

The Role of Laser-Based Wheel Monitoring Systems

Laser-based wheel monitoring systems use non-contact, optical sensors that capture how a wheel deforms the rail during transit. These sensors track even minute rail deflections, sometimes in the range of 100 nanometers (0.0001 mm). This enables detection of:

- Wheel flats

- Polygons

- Out-of-roundness

- Eccentricities

- Stochastic tread damage

The precision of these wheel profile diagnostic systems allows infrastructure managers to identify problems at the earliest stages, long before they escalate into safety risks or expensive repairs.

Why Wheel Load Measurement Systems Are Critical

Uneven wheel loading is a key contributor to infrastructure wear and vehicle instability. A wheel load measurement system tracks the vertical force each wheel applies, revealing:

- Overloaded axles

- Unbalanced bogies

- Asymmetrical loading

- Issues with suspension systems

Accurate wheel force data is crucial for maintaining track geometry, extending wheel life, and reducing long-term maintenance costs. In high-speed rail or metro networks, even small inconsistencies can cause vibrations, noise, and ride discomfort.

Key Defects Detected by Laser-Based Wheel Diagnostic Technology

Wheel Flats

These occur when part of a wheel slides instead of rotating, typically due to emergency braking or traction issues. A flat spot creates impact forces with every rotation, damaging both the wheel and track.

Polygons

A polygonal wheel has a periodically uneven circumference. These patterns, often caused by wear, generate cyclic forces that deteriorate track components and reduce ride quality. Laser-based systems detect these patterns in detail.

Out-of-Roundness

An out-of-round wheel rotates with eccentric motion, producing unwanted dynamic loading and uneven rail wear. Optical sensors track these deviations precisely, down to a fraction of a millimeter.

Stochastic Tread Damage

These are random and often unpredictable flaws caused by debris, weather, or mechanical failure. Because they don’t follow a consistent pattern, they are difficult to detect manually, making laser-based diagnostic systems invaluable.

How the Technology Works

The typical Wheel load measurement system includes:

A 4-meter measurement section embedded in the track

12 laser sensors (6 per rail)

A control cabinet housed nearby (typically 400 × 400 × 220 mm)

Data processing software with automatic calibration and error-checking

As a train passes over the sensors, the rail bends slightly under each wheel. The lasers measure the deformation at multiple points, creating a detailed force profile. The wheel’s position, velocity, and force signature are recorded and analyzed in real time.

The system also integrates with:

Automatic vehicle identification systems

Graphical reporting tools

Remote data upload to central servers or maintenance software

Benefits of a Laser-Based Wheel Profile Scanner

Adopting a wheel profile scanner with laser technology offers several operational advantages:

1. Non-contact measurement

There’s no physical contact with the wheel, meaning zero wear on sensors and uninterrupted measurement at full line speed.

2. Real-time data

Operators can monitor wheel health continuously and take immediate action when abnormalities are detected.

3. No service interruption

The system works under live traffic conditions. There’s no need for depot visits or line closures.

4. High precision

With nanometer-scale resolution and 10 kg force intervals, these systems outperform mechanical measurement techniques by orders of magnitude.

5. Self-calibrating

Once installed, the system automatically adjusts itself over time, reducing the need for manual intervention or recalibration.

Common Applications

Wheel force diagnostic systems are now in use across a variety of environments, including:

High-speed rail corridors

Urban metro systems

Freight and intermodal terminals

Light rail and tram networks

Railway maintenance depots for post-repair validation

They are particularly effective in harsh environments, where debris, heat, or cold might compromise visual or manual inspections.

Data Output and Integration of Lasca

Data from a laser-based monitoring system can be:

Exported in open formats such as

.csvor.txtStreamed to cloud platforms or centralized asset databases

Used for real-time alerting, graphical visualization, or historical trend analysis

Typical parameters include:

- Axle-by-axle load

- Number and depth of flats

- Wheel speed and position

- Deviation from roundness

- Priority status (e.g., urgent, monitor, OK)