Catenary Wire Wear Measuring System (CatPro)

Meet our advanced catenary wire wear measurement system (CatPro), an innovative solution for wear measurement.

OVERVIEW

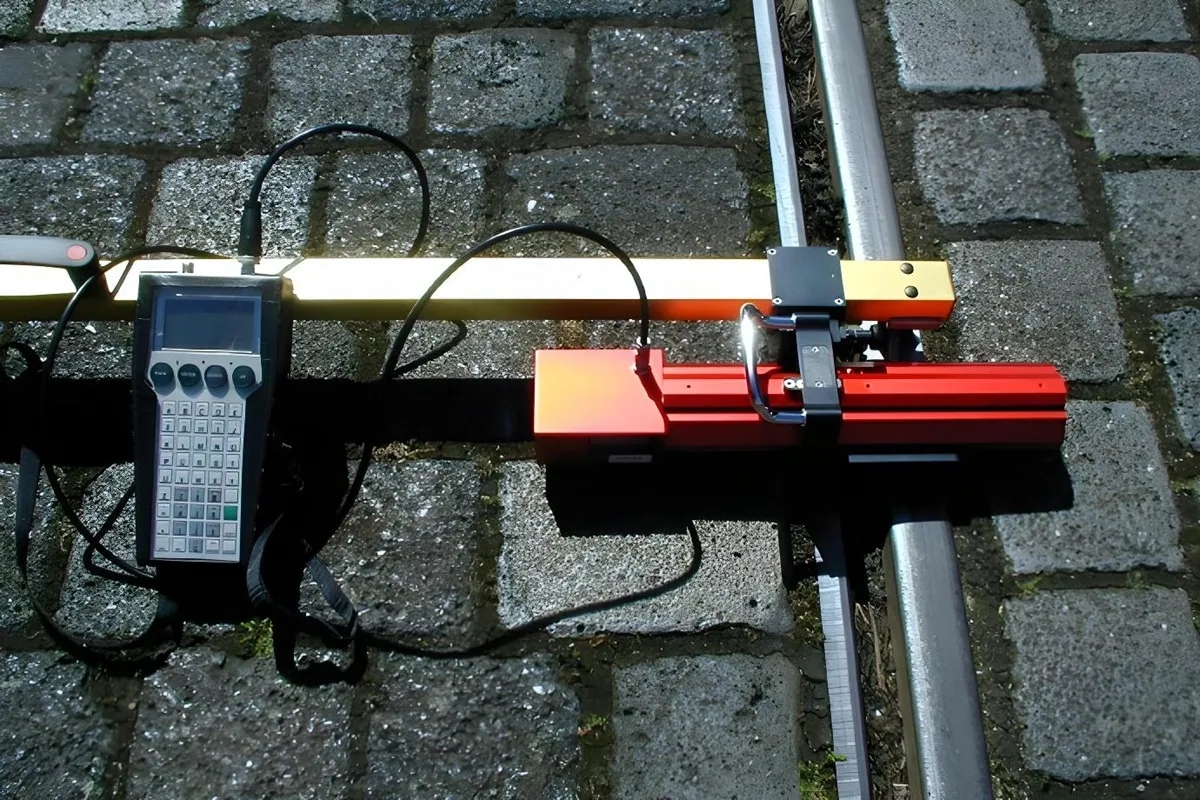

The CatPro is an advanced, automated optical solution for assessing contact wire wear in overhead electrification systems. Designed for integration into a pantograph, CatPro operates in live rail environments while the traction voltage is switched on, making it ideal for real-time, in-motion diagnostics without service disruption.

Using line lasers and synchronized high-resolution cameras, CatPro illuminates and analyzes the contact wire’s profile with high precision. Unlike traditional systems that rely on shadow measurements or height alone, it calculates the full cross-sectional area of the worn wire, offering superior accuracy even when the wire is twisted or installed under challenging conditions (e.g., bridges, tunnels).

The system has been successfully deployed by operators like VAG Nuremberg, who measured their entire network in just two night shifts using one high-railer.

It is also available as a standalone system or can be coupled with the OVHWizard to enable simultaneous measurement of wire wear, contact height, and stagger for a complete catenary condition profile. The system offers data export in open formats (e.g., .csv, .txt) for easy integration into external asset management platforms.

The most critical parameter that ADOR’s Catenary Wire Measuring System (CatPro) inspects is:

- Contact wire thickness (diameter/wear)

technical SPECIFICATIONS

The Catenary Wire Wear Measuring System is a compact, high-accuracy device designed for continuous, non-contact monitoring of overhead wire wear. Installed directly on the pantograph, it utilizes laser triangulation and high-resolution imaging to detect even minimal erosion in single and twin contact wire systems while the train remains in motion.

The technical specifications of the CatPro system are listed below. For further details and integration options, please download the catalog at the bottom of the page.

| Lateral position range: standard version ± 500 mm, larger lateral positions are possible on request |

| Measuring frequency: ≥ 40 Hz; next generation: > 100 Hz |

| Resulting intervals: 0.44 m at 160 km/h |

| Area accuracy: ± 3 % at 100 mm² |

| Max. twist angle: 45° |

| Accuracy angle of twist: 1° |

Gallery

Catalog

Please fill out the form to download the catalog:

Related Products

Contact Line Measuring System

Contact line height and stagger

Eddy Current Flaw Detectors

Mechanized scanning device

Ultrasonic Flaw Detector

Continuous mechanized testing

Rail Profile Measuring Device

Mobile Device

FAQS

What is the minimum detectable wear depth using CatPro?

CatPro can detect very small changes in contact wire diameter, down to fractions of a millimeter, ensuring early detection of wear before it becomes critical.

Can it measure wear on double contact wire systems?

Yes. It is specifically designed to support single and twin contact wire configurations, as used in many European and high-speed networks.

How do I get more information or request a quotation?

You can contact us directly through the website or email us at (info@adortech.com).

What is the scope of your work?

Our scope of work encompasses Canada and extends globally, offering tailored solutions for infrastructural and industrial needs.

Is any special training required to operate CatPro?

Minimal training is needed. The system is largely automated, and operators can quickly learn to manage the software and review logged data.

What Is a Catenary Wire Wear Measuring System?

The Catenary Wire Wear Measuring System, also known as CatPro, is an advanced railway monitoring tool designed to detect wear in overhead contact wires. Over time, as pantographs repeatedly glide along these wires to draw current, the contact area begins to erode. This wear can compromise electrical performance, introduce safety hazards, and escalate maintenance costs if left undetected.

CatPro solves this challenge by using a non-contact laser triangulation system combined with high-resolution cameras mounted directly on the pantograph. This setup enables continuous, automated overhead wire wear inspection without interrupting train operations or requiring manual intervention on the track.

Why Is Overhead Line Wear Measurement Important?

In electrified rail systems, the integrity of overhead lines is mission-critical. These wires must maintain precise contact with pantographs to provide consistent electrical power to trains. As they degrade due to friction, wear, weather exposure, and vibration, several issues can arise:

- Voltage instability

- Reduced current collection efficiency

- Overhead wire breakage

- Increased carbon buildup on pantographs

Operators can proactively plan maintenance and avoid unplanned service interruptions by investing in reliable overhead contact wire wear monitoring.

How Does CatPro Work?

The CatPro system integrates:

- Laser triangulation sensors to calculate the exact wire diameter

- High-resolution cameras for visual inspection and documentation

- Real-time processing software to log and interpret data

It mounts directly to the pantograph head and operates seamlessly while the train is in motion, making it ideal for integration with scheduled services or inspection vehicles.

CatPro is capable of detecting minute reductions in wire diameter, enabling timely corrective action and data-driven lifecycle extension strategies for the catenary infrastructure.

Key Features of CatPro

✅ Contactless Operation: Measures wear while in service—no disruption required.

✅ High Accuracy: Detects micrometer-scale variations in wire thickness.

✅ Dual Wire Capability: Supports both single and twin contact wire systems.

✅ Automatic Data Logging: Stores diameter and wear data for every measured segment.

✅ Real-Time Monitoring: Continuous data flow with camera-based confirmation.

✅ Pantograph-Mounted: Utilizes existing pantograph infrastructure for deployment.

✅ Integration Friendly: Can work alongside the OVHWizard and other diagnostic systems.

Applications and Use Cases

CatPro is designed to serve railway operators, infrastructure maintainers, and asset managers responsible for:

- Urban transit systems (metro, tram, and light rail)

- High-speed intercity rail networks

- Regional and suburban electric lines

- Electrified freight corridors

The system is especially useful in environments where:

- Contact wires experience accelerated wear due to frequent service

- Manual inspections are too risky or logistically complex

- Continuous monitoring is necessary due to high network load

CatPro has been adopted by leading railway operators in Germany, the Netherlands, Switzerland, and the UK, and continues to expand across other electrified rail systems globally.

Integration with the OVHWizard

CatPro is fully compatible with the OVHWizard—another flagship product that measures catenary height and stagger. When paired, these two systems form a complete overhead line monitoring suite:

OVHWizard covers vertical and lateral geometry

CatPro handles wear measurement and wire profiling

Together, they provide a complete view of the overhead contact system’s health, enabling predictive maintenance, real-time alerts, and trend analysis over time.

Benefits for Infrastructure Operators

By using CatPro, rail operators can:

Prevent costly emergency maintenance

Minimize service disruptions caused by unexpected wire failures

Extend the life of overhead contact systems through early intervention

Plan renewals with data-driven insights

Reduce manual labor and track occupation time

Ensure compliance with safety regulations and asset health standards