Ultrasonic Flaw Detectors

Reliable and portable ultrasonic flaw detectors are designed for precise non-destructive testing. Ideal for detecting internal flaws, cracks, and discontinuities in metals, welds, and composites across the Railway industry and inspection tasks.

OVERVIEW

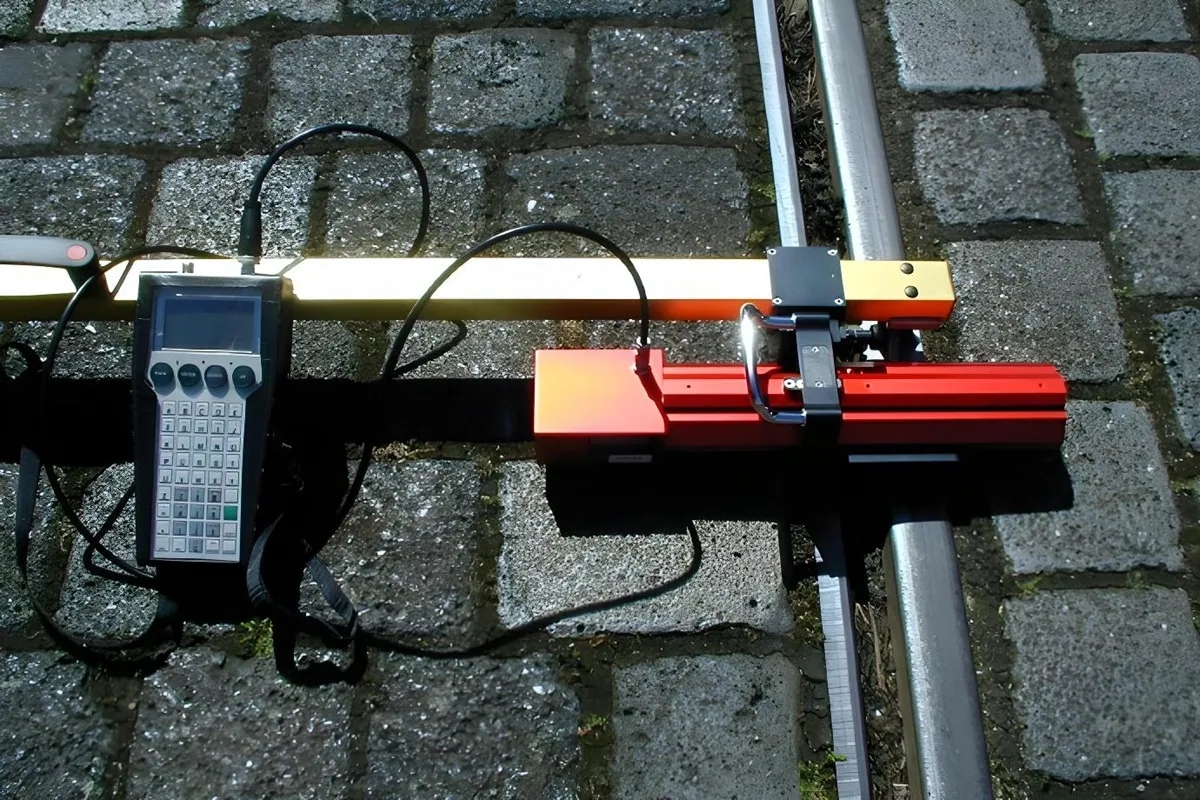

Our sophisticated ultrasonic flaw detectors are designed to inspect the rail track’s profile using ultrasonic testing systems. We offer double-rail, single-rail, and portable ultrasonic flaw detectors, operating in various projects with different needs. Our Ultrasonic single-rail flaw detector UDS2-77 SC can also be used for inspecting and testing tram rails, completing their operation package. ADOR’s ultrasonic flaw detectors are provided in various types to inspect and measure different components of rails.

Their primary applications are as follows:

- Identifying Transverse and Longitudinal Cracks and Cracks from Bolt Holes

- Identifying Corrosion

- Thickness Gauging

- Pre-Weld Inspection

- Welded Joints Testing

- Forging Testing

ModelS

OKOSCAN UT 73 HS

UDS2-73 SL

UDS2-73 RSUI

UDS2-73 RSUI

OKOSCAN 73HS

UDS2-77 SC

UDS2-77

USR-01

Sonocon B

Sonocon BL

ОKО-22М-UT

Technical SPECIFICATIONS

Our ultrasonic flaw detectors are engineered to meet the specific needs of our clients, offering customizable features and configurations.

The general technical specifications are listed below. For the complete specifications for each model in detail, please download the catalog at the bottom of the page.

| Testing Method: Pulse-echo, Echo-shadow, Contact & Immersion |

| Frequency Range: 0.2 to 27 MHz |

| Number of Channels: Single to Multi-channel (up to 200) |

| Display Type: 4.5"–10" Color Display or External Monitor |

| Protection Class: IP54–IP65, with rugged designs |

| Operating Temperature Range: -30°C to +55°C |

Gallery

Catalog

Please fill out the form to download the catalog:

Related Products

Eddy Current Flaw Detectors

Mechanized scanning device

Ultrasonic Thickness Gauges

Provides accurate thickness measuring

Contact Line Measuring System

Contact line height and stagger

Contact wire wear measuring

Continuously records the wear

Rail Profile Measuring Device

Mobile Device

FAQS

Do your flaw detectors come with software for data analysis and reporting?

Yes. Our detectors are equipped with specialized software, such as UT Basic, RailInspector, and OKO-UT Pipe, which enable real-time display (A-scan/B-scan), automatic defect logging, GPS-based mapping, and exportable inspection reports.

What types of defects can ultrasonic flaw detectors identify?

Ultrasonic flaw detectors can detect internal and surface defects such as cracks, voids, inclusions, corrosion, and thickness variations. They are especially effective in identifying sub-surface issues that are invisible to the naked eye.

How can I get more information?

Contact us for detailed technical documentation or tailored solutions to suit your project needs.

What is the scope of your work?

Our scope of work encompasses Canada and extends globally, offering tailored solutions for infrastructural and industrial needs.

Do your systems come with software and training?

Yes. All ultrasonic flaw detectors include specialized software for data analysis and reporting. We also provide manuals and virtual training options to get your team up and running efficiently.

What Is an Ultrasonic Flaw Detector?

An ultrasonic flaw detector is a nondestructive testing device that utilizes ultrasonic waves to detect interior and surface defects in different rail components. This efficient system is available for both portable and non-portable devices. The portable ultrasonic flaw detector is a mobile device with small dimensions that offers straightforward operation, while the non-portable ultrasonic testing flaw detector is designed with larger dimensions, passing on the rails (whether single rail or double rail) to detect defects.

How Ultrasonic Flaw Detection System Works?

Ultrasonic flaw detectors transfer high-frequency ultrasonic waves to different railway components to detect surface and subsurface defects. These sound waves travel at a specific speed, and if the reflected signals travel faster or slower than the norm, they can be referred to as a failure in that component. The inspection and testing process varies depending on the type of UT flaw detector (portable or non-portable), but the methods are the same.

The Benefits of Using Ultrasonic Testing Flaw Detectors

Ultrasonic flaw detection is a non-destructive testing (NDT) method by which the rail components and tracks are inspected without any damage to the railway infrastructure. By doing so, these efficient measurement systems can be an environmentally friendly and cost-effective solution. Moreover, it offers a straightforward process where the inspection is performed in a short time. Our UT flaw detectors are provided in portable and non-portable models, offering a time-saving railway inspection.

Best Portable Ultrasonic Flaw Detectors for Railway Inspection

Portable ultrasonic flaw detectors are ideal for field engineers who require flexibility without compromising accuracy. These devices are lightweight, rugged, and often equipped with high-resolution displays and digital data storage. They are especially useful for inspecting welds, axles, and joints in hard-to-access areas or when a quick on-the-spot evaluation is required. Models like Sonocon B and BL are known for their durability, precision, and user-friendly interfaces.

How to Choose the Right Ultrasonic Flaw Detection System

Choosing the right flaw detector depends on the inspection environment, the type of rail components, and the required testing speed. Portable units are suited for manual inspections and maintenance teams, whereas non-portable systems like OKOSCAN 73HS or UDS2-73 are optimized for high-speed, continuous rail monitoring. Important factors to consider include:

Number of testing channels

Detection accuracy and resolution

Speed of inspection

Compliance with industry standards (e.g., EN 16729-1, AREMA)

Applications of Ultrasonic Crack Detectors in Rail Infrastructure

Ultrasonic crack detectors are widely used in:

Detecting fatigue cracks in rail heads and weld zones

Measuring wall thickness of rails and pipes

Inspecting bolt holes and heat-affected zones

Conducting high-speed track inspection via trolley-mounted systems

These systems are critical in ensuring the safety, durability, and performance of railway networks.