Rail Surface Measurement Tool

To support the growing need for reliable rail infrastructure inspection in extreme Canadian weather conditions, ADOR was approached for the supply of a rail surface measurement solution to meet the requirements of our client, Metrolinx. The main challenge was to provide a walk-behind, human-powered device capable of capturing high-frequency, high-accuracy surface measurements across extensive rail networks. The system needed to function effectively without vehicle integration, with a precision threshold of ±0.5 mm, and operate reliably during the region’s severe winters and hot summers, as specified in the GO Transit Track Standards.

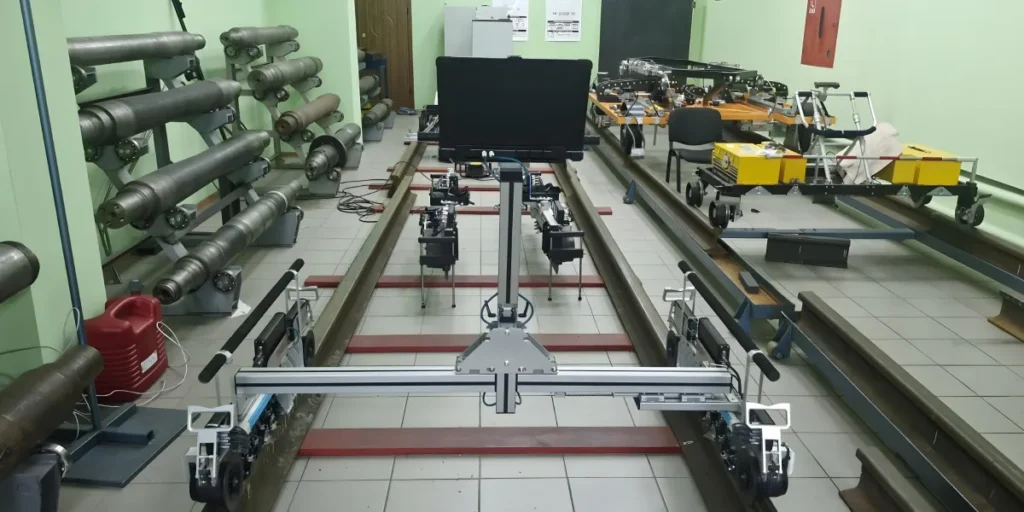

In response, ADOR supplied the ETS2-73 Eddy Current Double Rail Flaw Detector, a non-destructive rail surface inspection tool engineered for demanding field conditions, designed and manufactured by our partner, OKOndt. This solution was specifically chosen for its lightweight, manually operated design, precise defect detection capabilities, and full compliance with the required measurement frequency and environmental tolerances. The tool is capable of detailed surface scanning without the need for external power vehicles, making it ideal for dynamic and remote-use scenarios.

To ensure smooth deployment, we also facilitated training and integration support, enabling seamless adaptation to the end-user’s inspection procedures. This project reflects ADOR’s continued commitment to delivering technically sound, field-ready solutions for critical transportation infrastructure applications.

Location: Canada