Railway inspection was exhausting formerly. The different components of the rail tracks were destroyed to be inspected using special equipment, which incurred enormous cost and required a prolonged process. But today, railway specialists are utilizing non-destructive testing (NDT) methods to inspect different components of rail tracks, offering a cost-efficient, faster, and straightforward process. Ultrasonic testing (UT) is an NDT method widely used in railway maintenance and inspections. Understanding the applications of ultrasonic flaw detectors provides a better insight into how these systems can help to ensure safety and operation.

engineered for accuracy, speed, and long-term reliability:

Ensure precision in every rail inspection with our “Ultrasonic Flaw Detector for Rail Inspection“.

What Is Ultrasonic Flaw Detection in Railways?

Ultrasonic testing (UT) is a non-destructive testing (NDT) method where ultrasonic waves or pulses are transferred into the rail infrastructure to inspect the sub-surface and interior failures. By identifying discontinuity in the rail components, the ultrasonic waves are reflected back at a different speed. Ultrasonic flaw detection in railways is typically performed through three methods, depending on the types of defects. These methods include pulse-echo, angle-beam, and guided-wave rail testing, differing based on their wave propagation mode. However, here we delve into ultrasonic flaw detector applications more deeply as one of the most commonly used systems in the railway industry worldwide.

Explore our “Comprehensive Guide to Ultrasonic Rail Inspection Methods” to learn how different UT approaches ensure railway safety and efficiency.

4 Key Applications of Ultrasonic Flaw Detectors

Failures in rail infrastructures directly affect their safety, disrupting the railway operation and leading to potential hazards over time. This highlights the importance of regular rail inspection and maintenance more than ever. As mentioned before, ultrasonic flaw detection uses ultrasonic waves or pulses to detect defects in the rail infrastructure, ensuring they operate safely and efficiently. Understanding what defects ultrasonic flaw detectors can inspect and where these systems are used is crucial. Here, we provide the top 3 key applications of ultrasonic flaw detectors:

Rail Inspection

The primary application of ultrasonic flaw detection in railways is a comprehensive rail inspection to detect head, web, and foot defects, which are invisible to the naked eye. In other words, they can identify different types of head cracks (transverse, longitudinal, and horizontal), internal inclusions or laminations, vertical split head (web cracks), bolt hole cracks, fatigue cracks along weld-affected zones, transverse foot cracks, corrosion fatigue, and debonding or internal delamination.

Rail Weld Inspection

The integrity of rail welding plays a vital role in its safety and smooth operation. Failures in rail welds cause misalignments, noise (wheel clattering), and track vibration. Ultrasonic flaw detectors can identify defects in the rail weld joints, including lack of fusion, lack of penetration, incomplete welds, porosity (gas entrapment), slag inclusions, microcracks, and undercutting or overlap defects at weld edges.

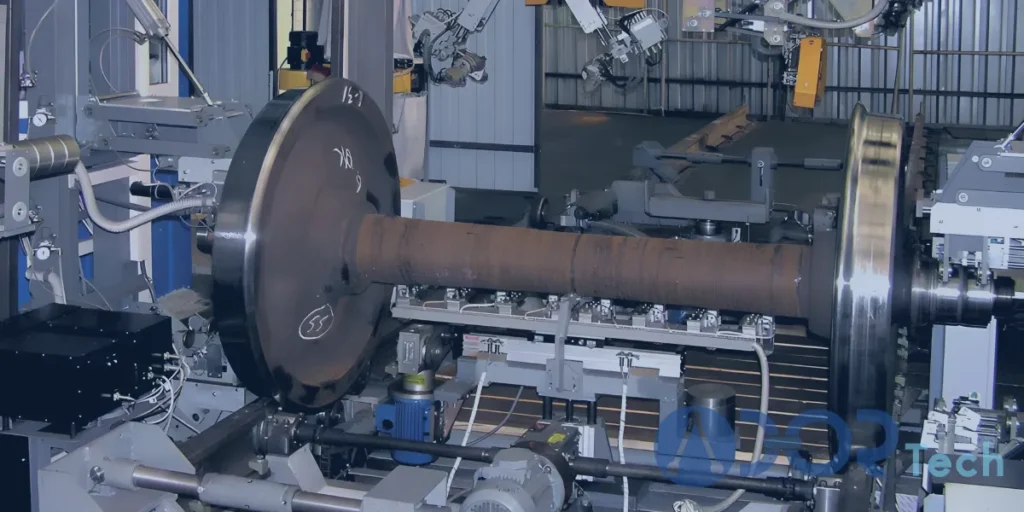

Railway Wheels and Axles Inspection

Ultrasonic flaw detector applications are not limited to the rail tracks. Rolling stock wheels and axles are also required to undergo regular inspection and maintenance to prevent sudden failures under heavy loads. These systems can detect axle defects, such as transverse fatigue cracks, longitudinal cracks, internal inclusions or voids, and subsurface fatigue damage. They are also able to inspect wheels, detecting radial cracks, circumferential cracks along the tread to flange, subsurface spalling or shelling defects, and internal porosity or inclusions in cast (forged) wheels.

Overhead Catenary System Inspection

Overhead catenary system (OCS) refers to the electrical wires or cables that supply the required electricity for electric trains or trams via a pantograph. Regular inspection of overhead catenary systems prevents hazardous and even fatal accidents. For instance, Dallas Area Rapid Transit (DART) trains caught fire recently, which could not have occurred if the overhead catenary system had been maintained or inspected regularly. Ultrasonic flaw detection uses ultrasonic waves to inspect the integrity of the overhead catenary system, ensuring its reliability and safety.

Types of Ultrasonic Flaw Detectors

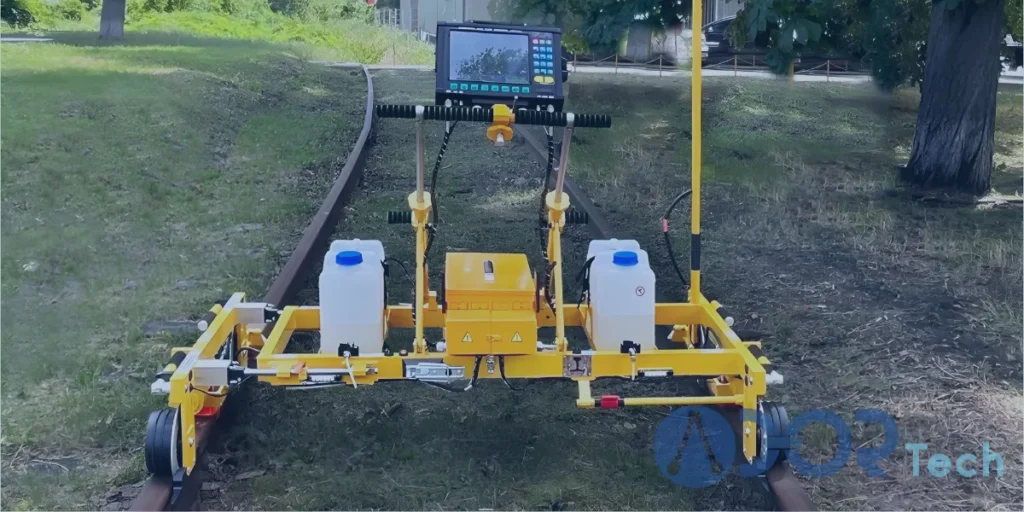

To understand how ultrasonic flaw detectors can ensure the safety and integrity of railway operations, it is crucial to deeply learn their types. First and foremost, ultrasonic flaw detectors are designed in 2 main types based on their mobility and operability: trolley-based and portable. Trolley-based ultrasonic flaw detectors include an ultrasonic flaw detector system mounted on a trolley, inspecting railways by travelling on it. Portable ultrasonic flaw detectors, conversely, are mobile devices, whether mounted on electric trains to inspect the overhead catenary system or handheld models used to inspect different rail components. Both trolley-based and portable UT systems provide reliable flaw detection and rail inspection due to their application.

Benefits and Challenges in Ultrasonic Flaw Detector Applications

As a non-destructive testing (NDT) method, ultrasonic testing (UT) offers a straightforward railway inspection rather than the old traditional methods, where the rail components were destroyed to be inspected. By identifying the potential failures in the rail infrastructure deep down, this method can be used as predictive maintenance and reduce the excessive costs of repair. At the core of this, ultrasonic flaw detection in railways ensures the safety of operations and smooth efficiency.

However, there might be some challenges when using the ultrasonic testing method. The precision and accuracy of the inspection depend on the ultrasonic flaw detector and the operator. The systems designed to offer maximum precision in railway flaw detection are typically integrated with cutting-edge technology, which might be more expensive. In addition, many of the ultrasonic flaw detectors cannot be used in all weather conditions, and their operation is limited due to the site conditions.

ADOR’s AI-Powered Ultrasonic Flaw Detectors

The sophisticated ultrasonic flaw detectors can offer more precise and faster rail inspection. At ADOR, we engineer our UT systems with high-end technology. They are supplied with advanced software that provides additional services and operations to enhance the detector’s inspection several times more. Integrated with Artificial Intelligence (AI) technology, our ultrasonic flaw detectors can pass the rail inspection tests successfully and operate with significantly high precision, accuracy, and speed. In addition to their efficient flaw detection, our advanced UT flaw detection systems can provide comprehensive post-analysis reports to optimize the railway maintenance and inspection.

Conclusion

Ultrasonic testing (UT) is a non-destructive testing (NDT) method, where the railway infrastructure is inspected via ultrasonic waves to detect interior defects. Understanding the applications of ultrasonic flaw detectors in the railway industry is necessary due to the benefits this method offers, including maintenance process simplification, prediction of potential failures in railway infrastructure, preventing excessive costs of repair, and ensuring the railway’s operational integrity and safety. Ultrasonic flaw detection in railways offers challenges; however, using sophisticated systems minimizes their limitations and allows more precise and faster inspection.