Surface defects appear on the rail track surface when it consistently contacts rolling stock wheels, environmental impacts, or heavy loads. Ignoring these apparently insignificant defects can incur deeper and more serious failures in the railway infrastructure, which can lead to hazardous incidents. To ensure a safer network and operation, non-destructive testing (NDT) is used, providing various methods suitable for every inspection type. Eddy Current Testing (ECT) is one of the most common and reliable NDT methods used to detect head defects in rail tracks. Let’s delve more into what Eddy Current Testing in railways is, how it can detect rail defects, and why it plays an essential role in ensuring a safer railway network.

What Is Eddy Current Testing in Railway?

In simple terms, Eddy Current Testing (ECT) is a non-destructive testing (NDT) method that detects the tracks’ surface defects. A coil with an Alternating Current (AC) is placed near the rail track or the component that is supposed to be inspected and generates a magnetic field around it. This field interacts with the rail track’s conductive metal and induces the circular eddy currents within it, which create their own magnetic field opposed to the original one. Head cracks, corrosion, wear, fatigue, and any other failures in the rail surface or just below disrupt the eddy currents, allowing eddy current flaw detectors to detect the defects.

Eddy current flaw detectors include probes; each contains one or more coils to generate the primary magnetic field. When the eddy currents are disrupted due to the existence of a failure in the rail surface infrastructure, the eddy current flaw detector signals to the operator. Most of the ECT flaw detectors are equipped with a monitor or laptop, indicating the exact location and type of defect.

Why Eddy Current Rail Inspection Is Crucial?

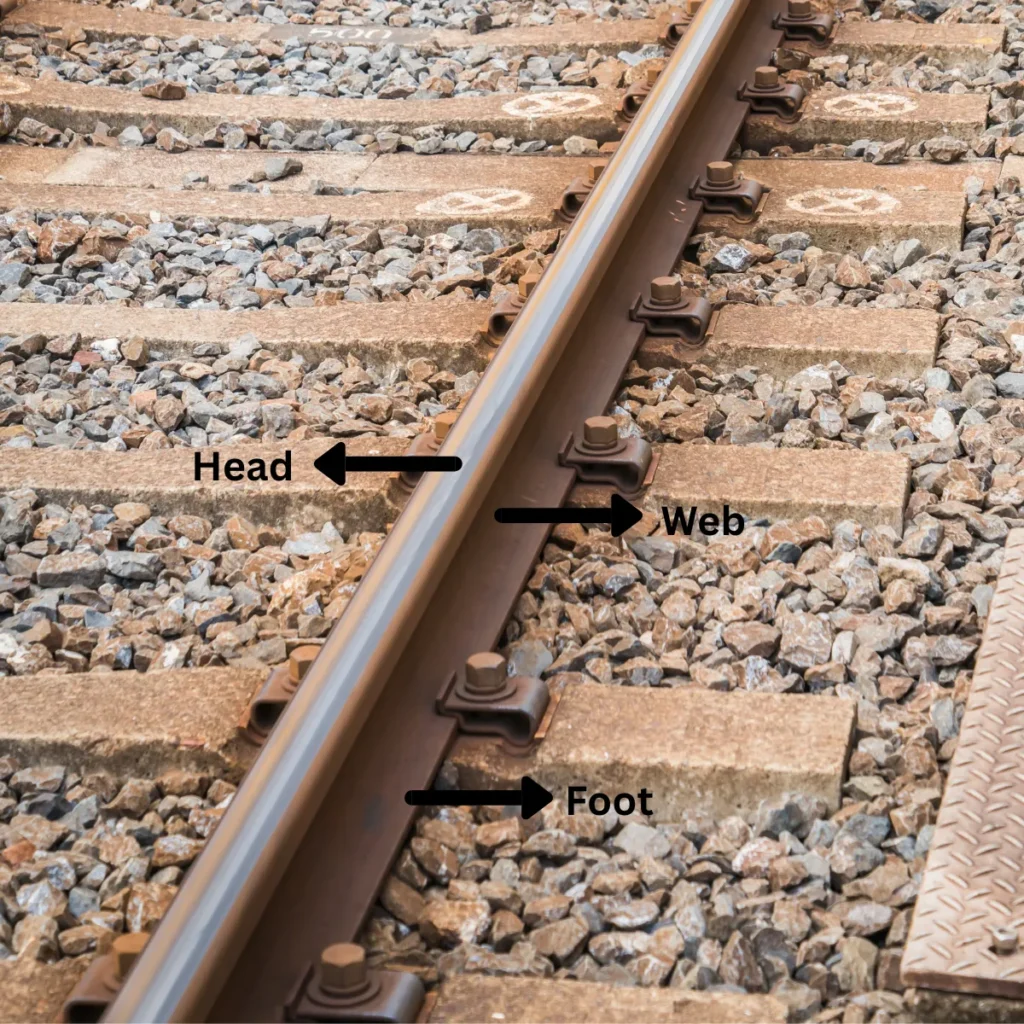

Rail tracks include three main parts: head, web, and foot. Consistent contact with the rolling stock wheels, heavy loads, and high speed can lead to potential head and sub-head failures that disrupt railway safety and operation. Harsh weather conditions (especially extremely cold weather in North America), on the other hand, can damage rail heads over time.

Ignoring these surface defects allows them to grow and even causes failures in the web parts of rails. As a non destructive rail testing, eddy current flaw detection identifies the surface and sub-surface defects, avoiding hazardous incidents or deeper failures that incur more costs for repair. By detecting a wide range of head cracks, wear, corrosion, corrugation, and fatigue, eddy current rail inspection ensures rail safety and operational integrity.

Real-Time Rail Inspection with Eddy Current Testing: Pros and Cons

When it comes to choosing an NDT method for rail inspection, understanding what benefits and challenges it offer has always acted as a guide. Eddy current rail inspection is a non-destructive testing method that not only detects surface rail defects but also provides a comprehensive inspection without damaging the rail infrastructure. In addition, it is a versatile inspection method used not only for railway applications but also in diverse industries. Here are the most common and primary advantages and disadvantages of eddy current testing in the railway industry:

Advantages of Eddy Current Testing

Speed is one of the most significant factors in the context of non-destructive testing (NDT) methods. The rail eddy current NDT method offers a contactless inspection that detects the surface and sub-surface defects at high speed. This is why eddy current rail inspection is one of the methods widely used because of its time-saving capability. Moreover, since no destruction or damage to rail infrastructure is needed, eddy current testing is more straightforward and cost-effective.

This method also addresses sustainability and eco-friendliness due to its inspection process. In terms of technical advantages, the rail eddy current NDT method comprehensively inspects the rail heads and just below to detect the surface defects, ensuring the rails’ lifetime. Therefore, it can be an efficient tool in rail maintenance projects.

Disadvantages of Eddy Current Testing

Alongside its advantages, eddy current rail inspection also presents some challenges and limitations. This method is only used for rail head inspection and detecting surface defects, such as head cracks, wear, corrosion, corrugation, and fatigue. So, it is not efficient to inspect deeper rail infrastructure (e.g., web and foot), which limits its applications.

Due to the requirement of conductive metal in the rail infrastructure to be able to generate magnetic fields, eddy current testing is not capable of working on other types of railways, like wood. In addition, defect detection in this method mostly depends on the device precision, the number of probes, and the technology. Therefore, it should not be expected that all eddy current flaw detectors provide the same performance.

See also: “Eddy Current vs Ultrasonic Testing“

The Future of Non Destructive Rail Testing and Eddy Current Inspection

With the development of technology, most of the non-destructive testing methods are upgraded and integrated with Artificial Intelligence (AI) and Machine Learning (ML). These cutting-edge technologies help the inspection systems detect rail defects in a smarter, faster way. They will also be able to provide a technical analysis report of their inspection, not just the location of failures. However, there are some sophisticated eddy current rail inspection systems that follow the trend of technologies today. They can easily inspect the rail track, detect surface defects, and provide a technical analysis report in just a few seconds.

Conclusion

In summary, railway eddy current testing is a common non-destructive testing method used to inspect the railhead. By detecting surface or sub-surface defects on rail heads, eddy current rail inspection not only ensures the railway safety and operational integrity, but also guarantees the rail’s prolonged efficiency. Like any other inspection method, the rail eddy current NDT method offers benefits and challenges.

It is a versatile, sustainable, cost-effective, and time-saving method that plays a crucial role in ensuring rail safety. However, eddy current rail inspection is suitable for the rail head inspection (not web and foot), and operates only on conductive materials, which limits its efficiency in maintenance projects. Although eddy current testing is still one of the most reliable NDT methods in the railway industry.