When it comes to railway inspection, the debate of eddy current vs ultrasonic testing is one of the most important considerations. Today, non-destructive testing (NDT) is recognized as a profitable inspection method in various industries, especially in railways. By simplifying the flaw detection process, it surpasses the traditional destructive testing. Among the NDT methods, ultrasonic and eddy current testing are two common and reliable methods used in railway maintenance. Because of their benefits, choosing between these methods has always been a challenge. Here, we aim to compare ultrasonic and eddy current testing methods in detail based on the critical factors, including inspection methods, reliability, setup requirements, and applications.

Looking for advanced solutions in ultrasonic rail inspection? Explore our “Ultrasonic Flaw Detector“.

Eddy Current vs Ultrasonic: A Comparison of the 2 Best NDT Methods

Regular maintenance is a priority in the railway industry to ensure the safety and integrity of operations. At its core, railway specialists and companies are often seeking the best method that provides maximum efficiency at minimum difficulty and cost. This is why the question “which railway inspection method is the best?” has always remained an unsolved puzzle. Ultrasonic and eddy current testing are among the best NDT methods that are commonly used in railway maintenance. We will compare these two methods in detail based on the critical factors to reveal which is the best. Let’s start!

Detect surface and near-surface defects faster with our “Eddy Current Flaw Detector“, trusted for efficient railway inspection.

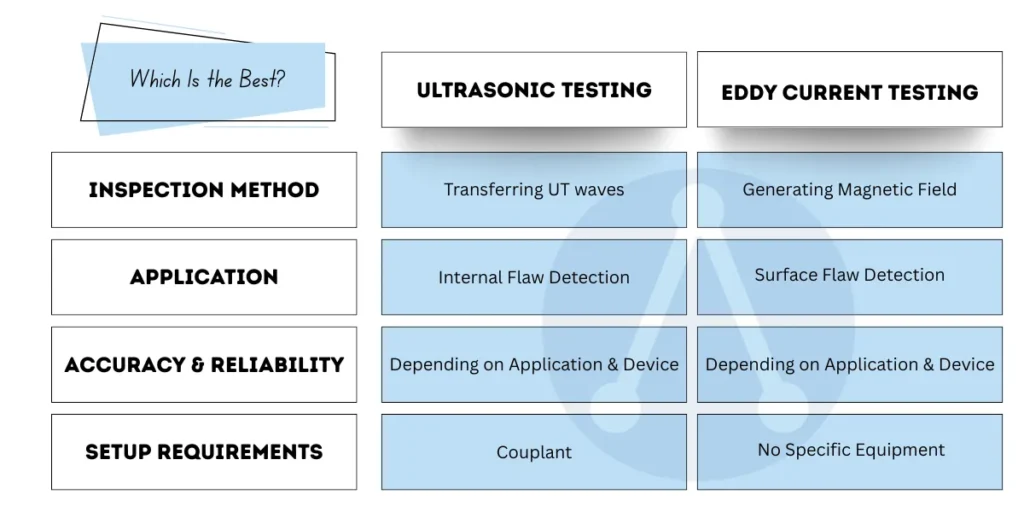

Inspection Method

Ultrasonic and eddy current testing follow distinctly different methods. In ultrasonic rail inspection, the ultrasonic waves are transferred into the railway infrastructure. These waves are travelling at a specific speed. If there are any failures or distances in the material, the ultrasonic waves are reflected back at different speeds. Eddy current rail inspection, on the other hand, uses a coil with an alternating current (AC) to generate a magnetic field that induces circular eddy currents within the rail by interacting with the conductive metal. Another magnetic field is generated from eddy currents, opposed to the first one. If there are any defects in the rail infrastructure, the eddy currents are disrupted.

Want a deeper look into how ultrasonic testing works? Check out our detailed guide on “Ultrasonic Rail Inspection Methods“.

Applications

Ultrasonic and eddy current testing methods are widely used in various industries, but here we address their railway applications. They both offer an inspection of rail tracks, wheelsets, and axles, but in different ways. Ultrasonic testing inspects the internal and deep flaws, while eddy current testing inspects the surface flaws. In other words, ultrasonic testing is often used to detect internal cracks and corrosion in rail, weld zones, wheelsets, and axle boxes. However, eddy current testing typically inspects track switches, welded joints, gauges, wheelsets, and axle boxes to detect surface and near-surface flaws.

Curious about where ultrasonic testing is most effective? Read our blog post on the “Top 4 Applications of Ultrasonic Flaw Detectors“.

Accuracy and Reliability

The accuracy and reliability of these methods depend on two factors: application and device. Ultrasonic rail inspection is used to detect internal defects, and eddy current rail inspection is used to detect surface or near-surface flaws. Therefore, ultrasonic testing may miss the small surface cracks, and eddy current testing cannot inspect the deep infrastructures. Secondly, the device used directly affects the accuracy and reliability of the inspection. If the ultrasonic flaw detector is not accurate enough, it is not able to detect the defects properly. Same in eddy current flaw detectors! If they are not accurate enough, they miss fractional defects that cause potentially significant failures.

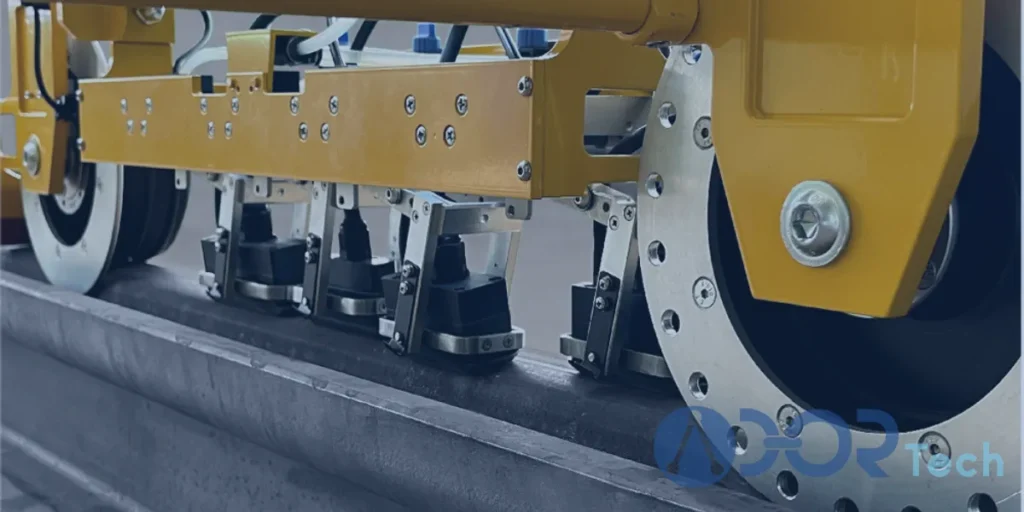

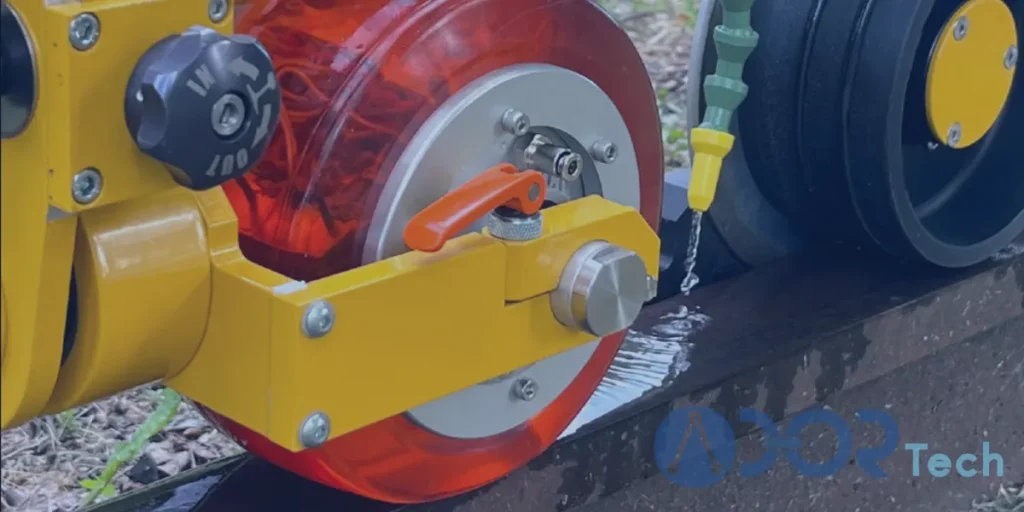

Setup Requirements

Ultrasonic rail inspection requires couplant. Couplant is a gel or liquid substance that eliminates air gaps and provides acoustic continuity between the rail surface and the ultrasonic flaw detector, ensuring a more accurate and efficient inspection. Eddy current rail inspection, conversely, does not require couplant. Still, due to the generation of magnetic fields, any disconnection to the inspected component or lift-offs can disrupt the defect detection process. However, setup requirements can be relied on the type of flaw detection, too. Some of them require additional equipment to inspect the different railway components.

Which Method Is the Best: Ultrasonic vs Eddy Current

Which method is the best? This is a question that came up after comparing ultrasonic and eddy current testing. To answer that, it is required to consider what application it will be used for. Ultrasonic rail inspection best suits deep infrastructural flaw detection, while eddy current rail inspection is suitable for detecting surface defects. This is the main factor that determines which method is the best for the railway project. But a combination of these two methods ensures that no flaws are missed, whether internal or surface ones. Therefore, rail specialists typically use both ultrasonic and eddy current testing methods together.

Kill Two Birds with One Stone: Here Is ADOR’s Solution

Providing an ultrasonic flaw detector and an eddy current flaw detector, one for inspecting internal infrastructure and one for surface, may incur an excessive cost. At ADOR, kill two birds with one stone! We are developing a versatile system that supports both ultrasonic and eddy current testing. By using and paying for just one device, the railway safety and operational integrity are ensured. This solution not only reduces the excessive costs but also simplifies the inspection process. Beyond that, our current ultrasonic and eddy current flaw detectors are engineered with high accuracy and speed, detecting railway defects efficiently. ADOR’s ultrasonic flaw detectors are also going to be integrated with Artificial Intelligence (AI) technology for enhanced inspection.

Conclusion

In summary, understanding different rail inspection methods provides a better vision to choose the suitable one. Ultrasonic and eddy current testing are two common non-destructive testing (NDT) methods used to detect railway defects, ensuring its safety and operational integrity. In this blog post, we compare these two methods based on their inspection methods, applications, accuracy and reliability, and setup requirements. By delving into what each one is suitable for and how they differ, decision-making becomes easier.